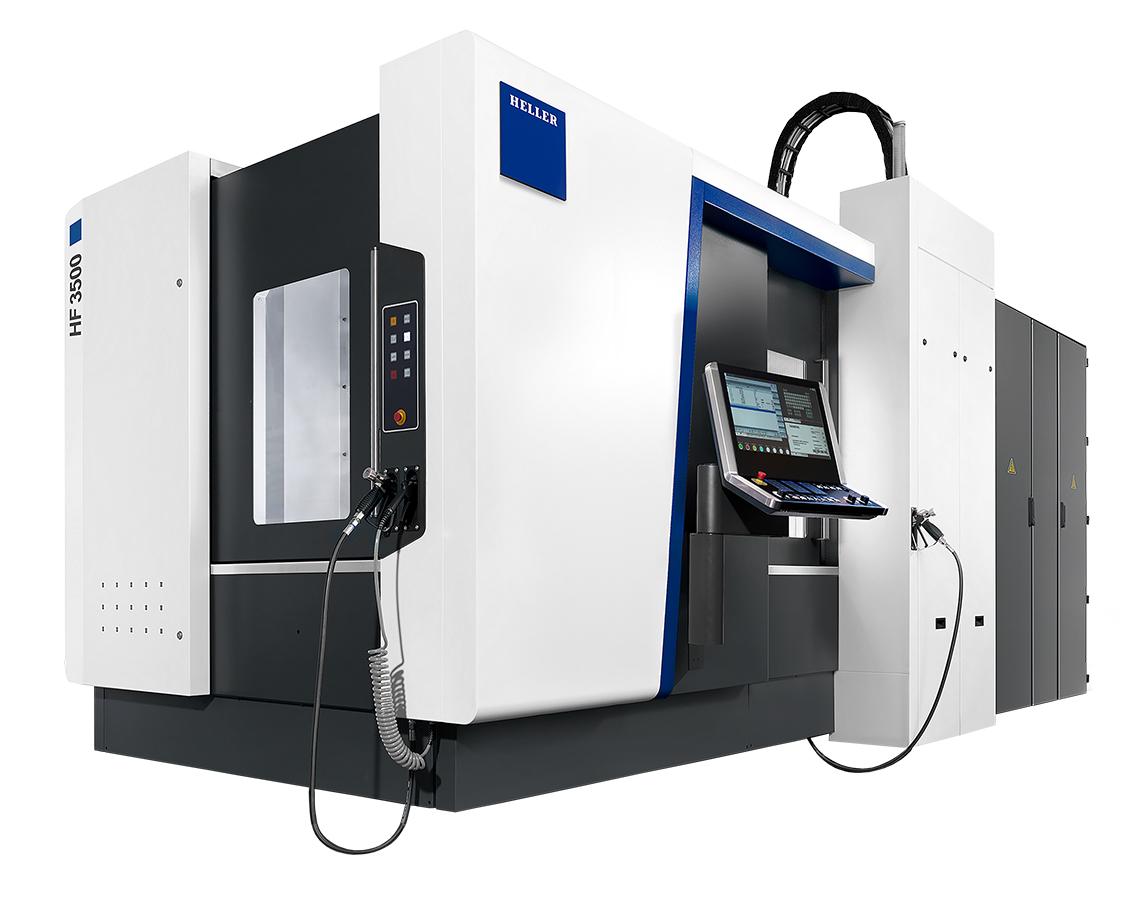

H Series

The H Series 4-axis horizontal machining center from HELLER offers highly productive machining in a diverse range of applications. The H Series features high table load capacity, reduced energy consumption, extended tool life, high performance and precision machining, and is capable of handling a dynamic range of batch sizes, part sizes, and materials. Additionally, The H Series offers options for fully customizable spindle, spindle taper, tool magazine, and chip disposal.