We minimize your downtime so you can

MAKE MORE

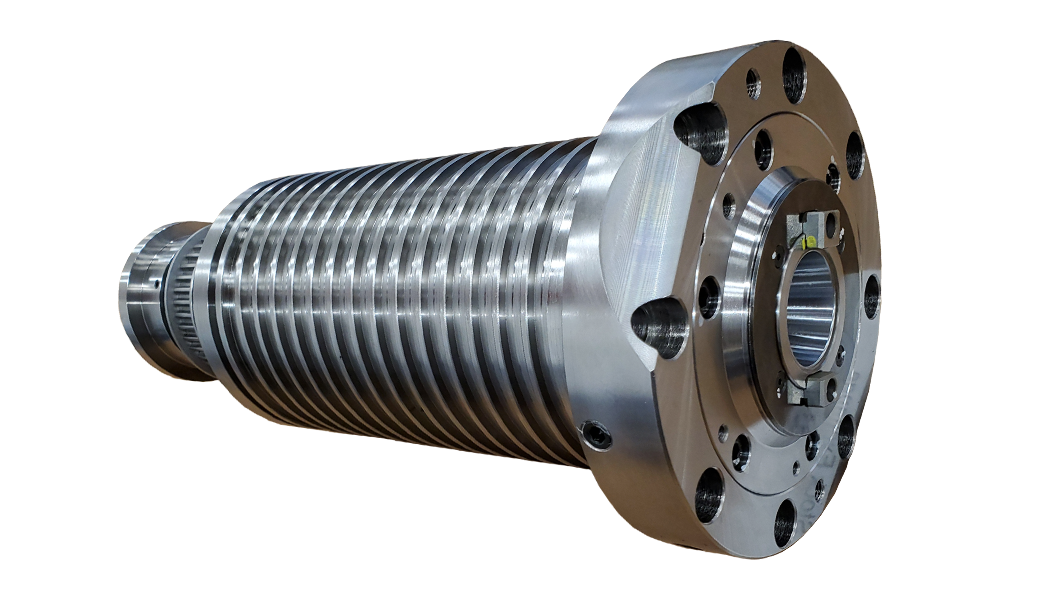

Spindle Rebuilds at Ellison Technologies

At Ellison Technologies, we specialize in providing top-tier spindle rebuild services to minimize downtime and maximize your CNC machine's efficiency. With over 70 years of experience, our factory-trained engineers ensure each spindle is rebuilt to meet or exceed OEM specifications, backed by a one-year warranty when installed by our team.

Spindle Rebuild Concierge Program Benefits

Ensure your rebuilt spindle is always in peak condition and ready to go when you need it most.

– Secure Crating & Climate-Controlled Storage

– Priority Reservation

– Biannual Care & Inspection

– 1-Year Warranty

Exchange spindles help eliminate downtime so you can continue to MAKE MORE.

Our Ellison Technologies Spindle Rebuild facility has various Doosan and Mori Seiki rebuilt spindle styles in stock and ready to ship today. To further reduce downtime, we offer an exchange program with various Doosan and Mori Seiki rebuilt spindle styles in stock and ready to ship. If your specific spindle isn't available, we can expedite the rebuild process to get you back up and running swiftly.

Have extra spindles lying around? Let us know; we can make you an offer to purchase your old spindles or rebuild for your stock.

Thank you for your techs on the horizontal spindle [exchange]. Please tell your team, “Great Job.” We are back in production! With no question, slam dunk, my next horizontal will be another Doosan.

Our Spindle Rebuild Process Includes:

Thorough Inspection and Cleaning: Each spindle undergoes a meticulous examination to identify wear and damage.

Component Replacement: We replace all bearings, preload collars, and O-rings with components that meet or exceed OEM standards.

Precision Assembly: Spindles are assembled in a clean room environment, ensuring optimal performance.

Quality Assurance: Final inspections and performance tests guarantee your spindle operates at peak efficiency.

Replace all bearings, preload collars, and O-rings with components that meet or exceed OEM specifications.

Bearing preloads are fit to the spindle shaft and housing, preload collars and spacers are ground to size.

Spindles are cleaned, detailed, and inspected to ensure they meet OEM standards.

Spindle is assembled in a clean room with final inspections conducted to ensure performance meets OEM specifications.

If applicable, the drawbar is cleaned, greased, and tested for secure tool retention.

Bearing preloads are fit to the spindle shaft and housing, preload collars and spacers are ground to size.

All steps throughout the process are thoroughly documented and photographed: Spindle arrival, disassembly, inspection, performance measurements and final packaging.

I've been working with Kim on a spindle rebuild for my NT4250 and I wanted to let you know it was a pleasure working with her. She was very prompt with replies to any questions I had, she's very pleasant to work with, thanks.

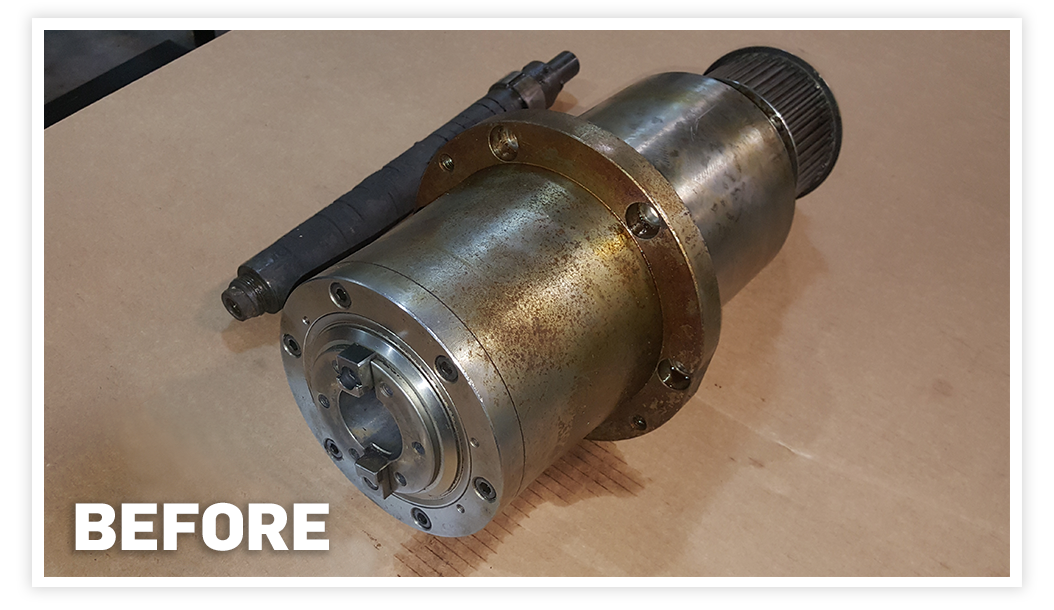

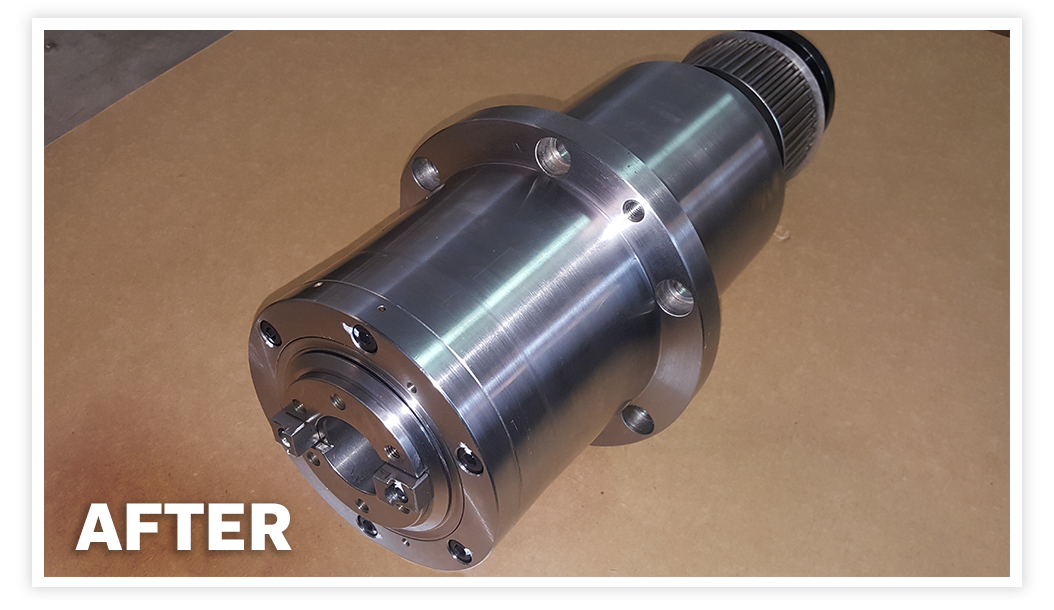

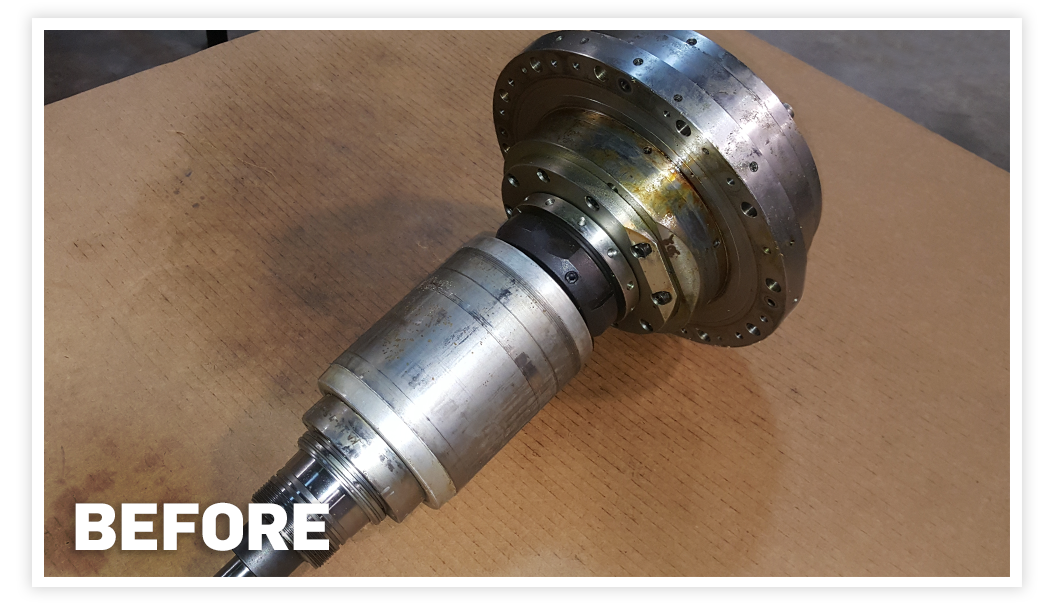

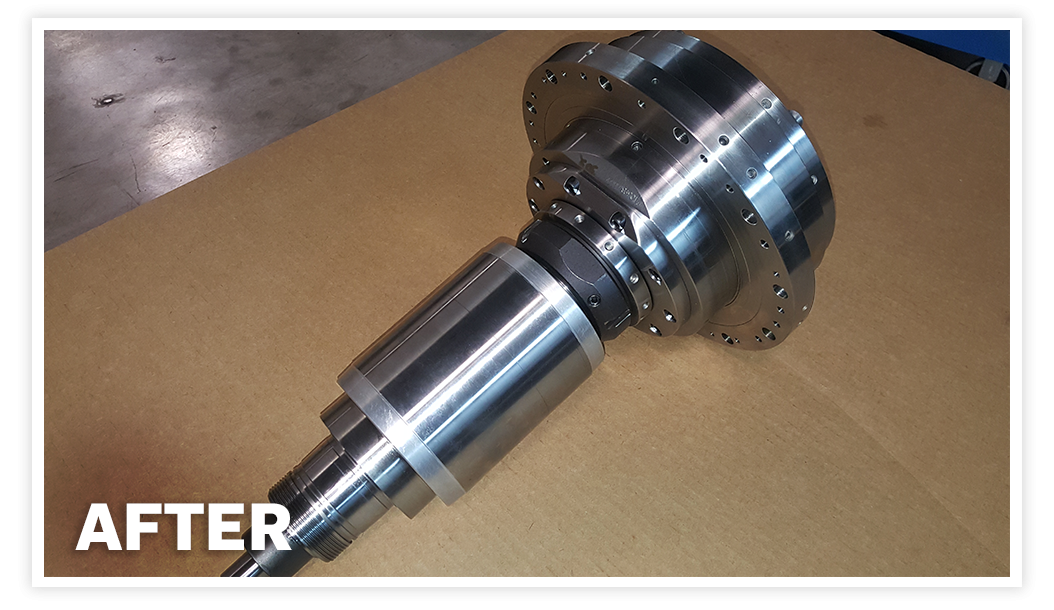

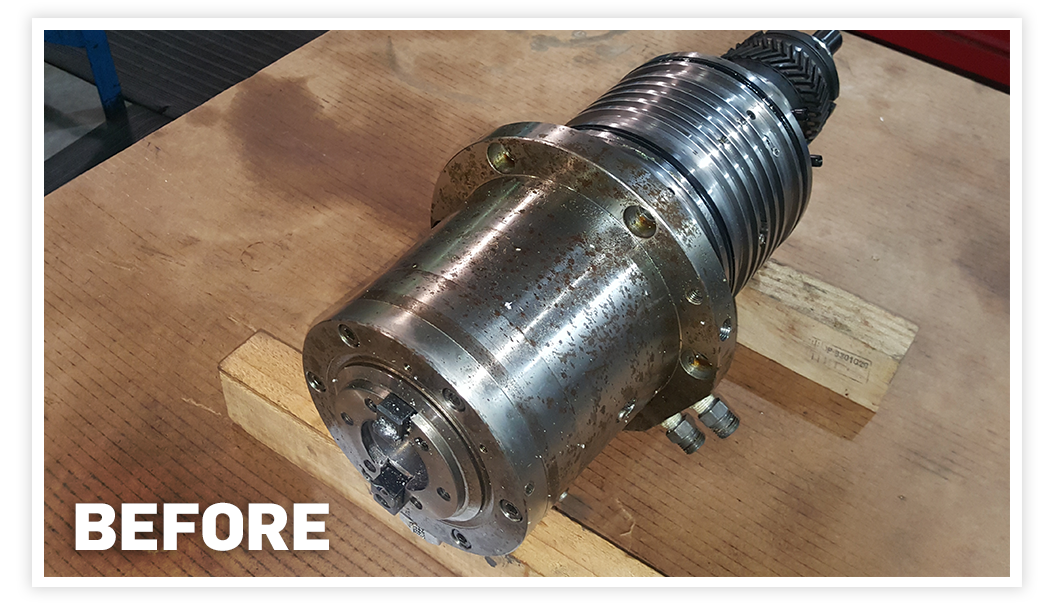

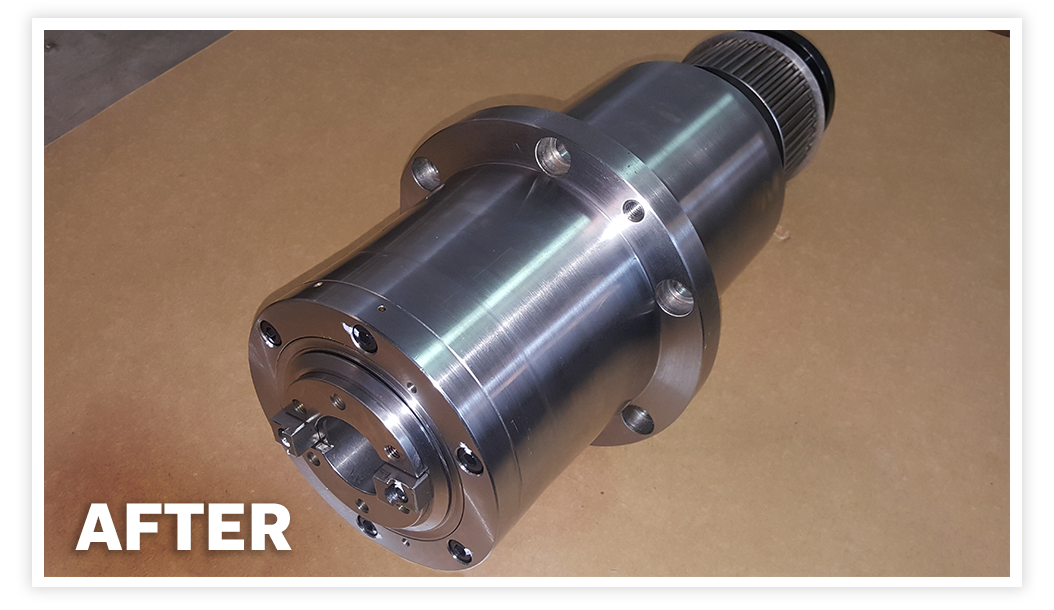

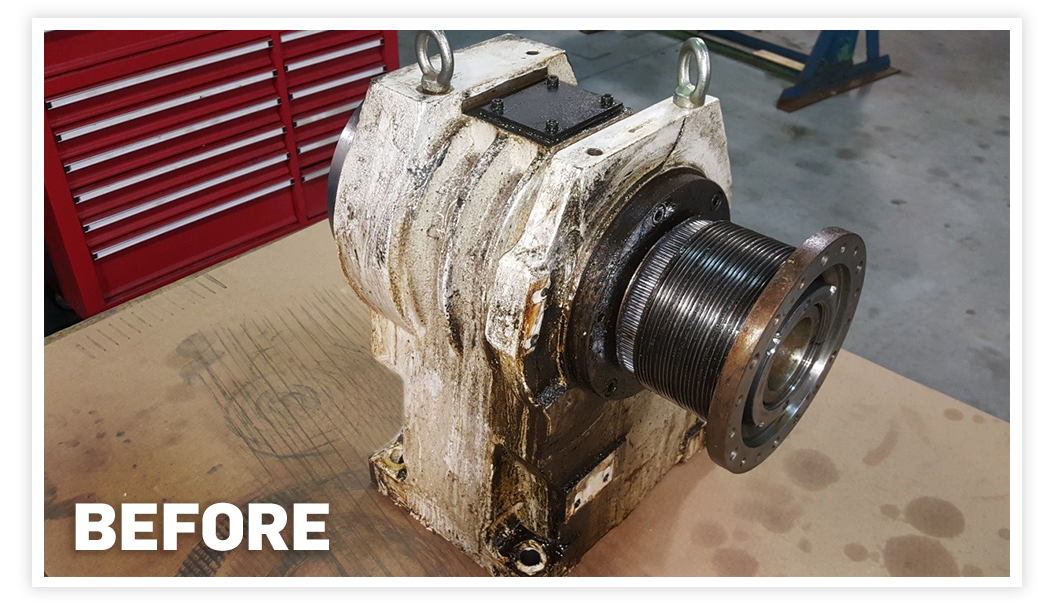

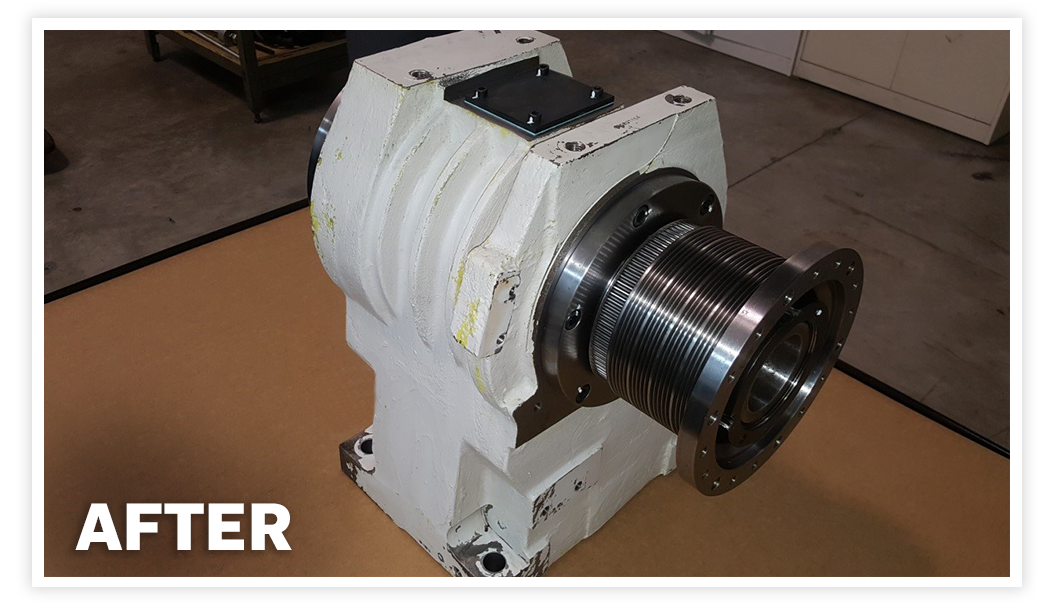

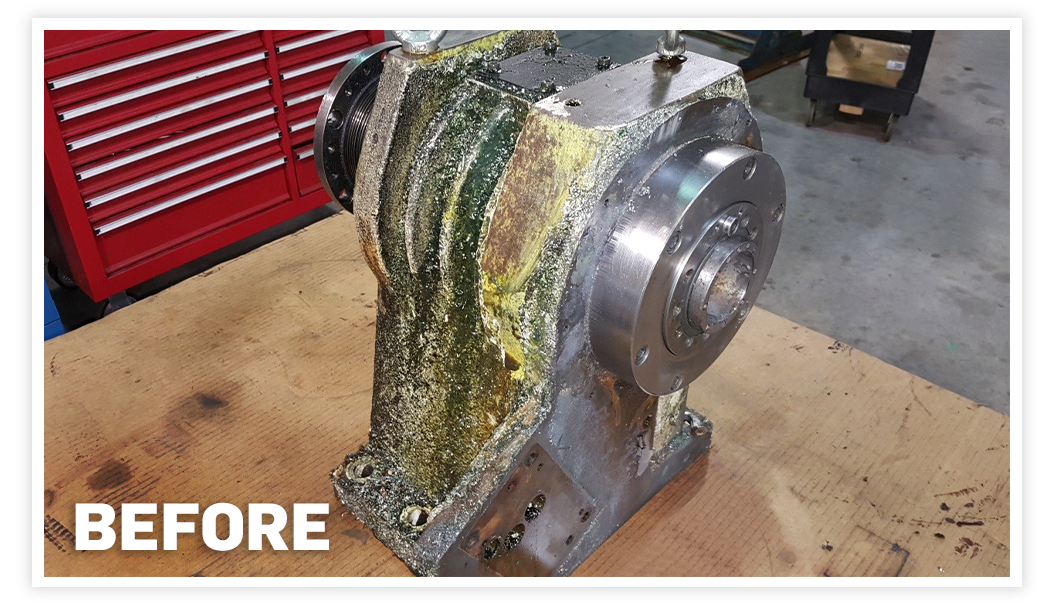

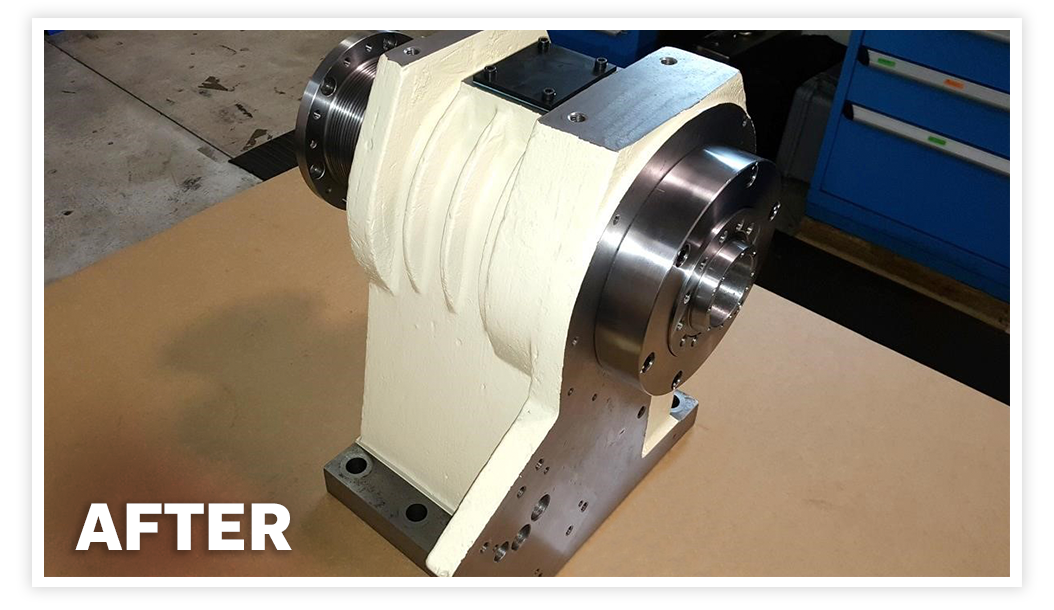

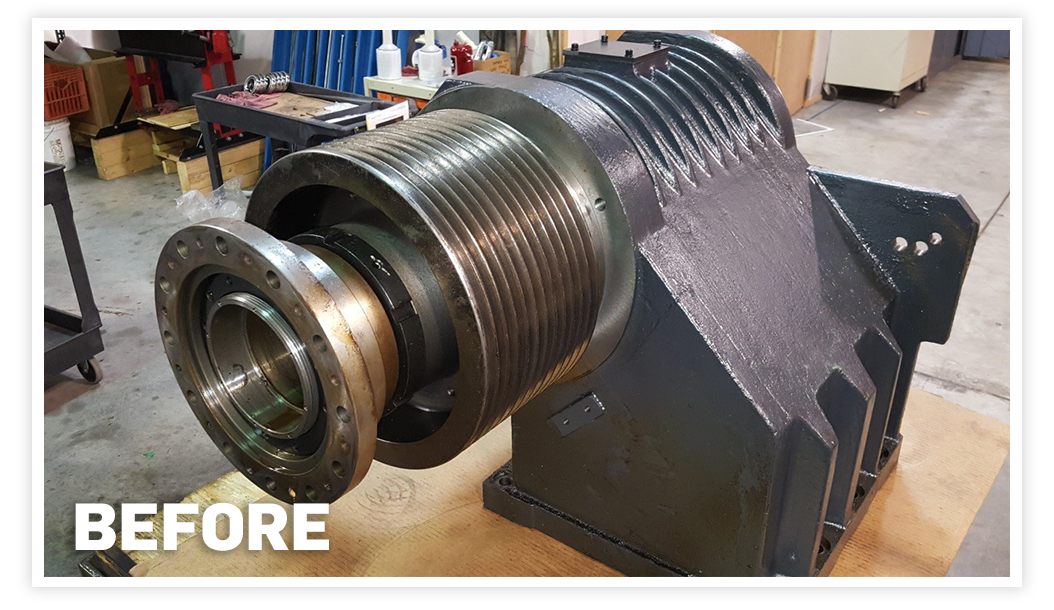

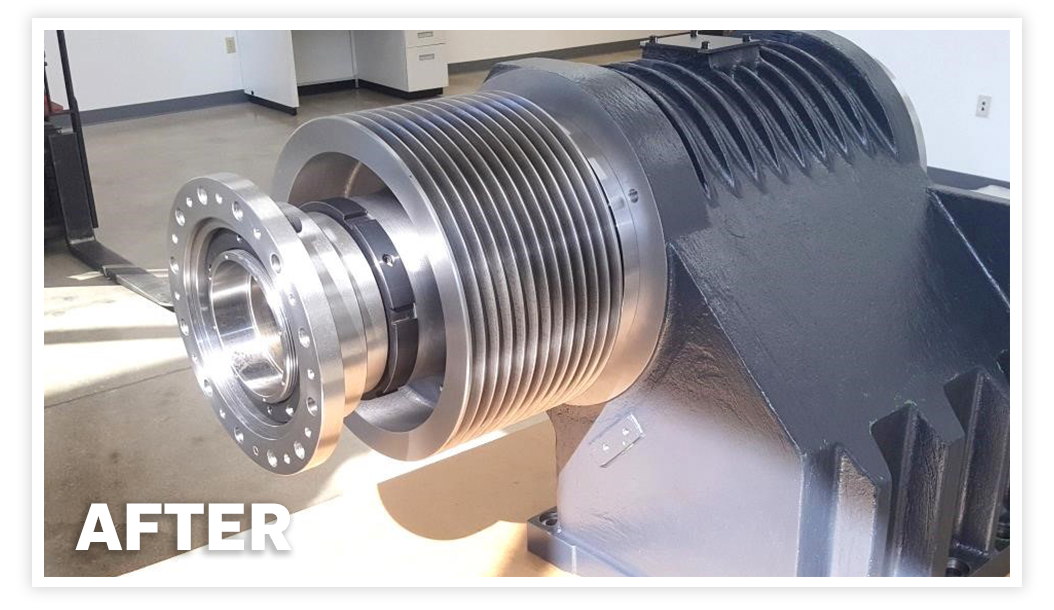

Spindle Rebuild Before & After Photos

DMV 4020 Spindle Rebuild

|  |

NTX 2000 Spindle Rebuild

|  |

DMV 6030 Spindle Rebuild

|  |

Lynx 200 Spindle Rebuild

|  |

Lynx 200A Spindle Rebuild

|  |

PUMA 400B Spindle Rebuild

|  |

Let our experts keep your spindle production-ready.

We specialize in spindle, taper and shaft repair on most makes and models, including DN Solutions (Doosan), Hitachi Seiki, Mori Seiki, Okuma, Mazak, and many more.

Need your spindle back faster? Ask about our expediting services. We are your ONE CALL for all your CNC support needs!

For Spindle Support Call: (262) 523-3405