Markforged 3D Printing

Markforged 3D Printing

Unlock the full power of industrial 3D printing with Markforged solutions from Ellison Technologies. Whether you are exploring composite, continuous fiber, or metal additive manufacturing, each Markforged system is engineered to deliver unmatched precision, durability, and repeatability right on your production floor.

On this page, you will find a clear breakdown of each printer platform, what it is designed to do, and how it fits into real-world manufacturing workflows. You will also see proven application examples, including inspection fixtures, soft jaws, and functional prototypes that showcase significant time and cost savings achievable with Markforged technology.

Transform how you design, validate, and produce parts with an additive workflow built for industrial performance. Contact us to learn which system aligns with your production goals.

Metal X System

The Metal X system offers a safe and affordable solution for producing functional metal parts. It eliminates the need for dedicated operators and complex powder management systems, making metal 3D printing more accessible.

Safe and Affordable:

The Metal X 3D printing system is safe, affordable, and accessible for all fabricators. It is more cost-effective than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

Quality Parts, Fast:

The Metal X is designed to consistently produce high-quality parts and provide a user-friendly experience. Markforged utilizes cutting-edge software and advanced motion systems to deliver industrial-grade parts.

Additive Application Case Study:

Inspection Fixture

70%

FASTER

Lead time went from

10 days → 3 days

80%

LOWER COST

Cost went from

$1,590 → $330

High Dimensional Accuracy

Precision-machined hardware creates stiff, strong, and accurate fixtures to measure part tolerances quickly.

Custom Fit

Test against design intent with form-fitting fixtures that verify parts are within spec.

Save Time & Money

Quickly produce intricate, form-fitting fixtures at a fraction of machined cost.

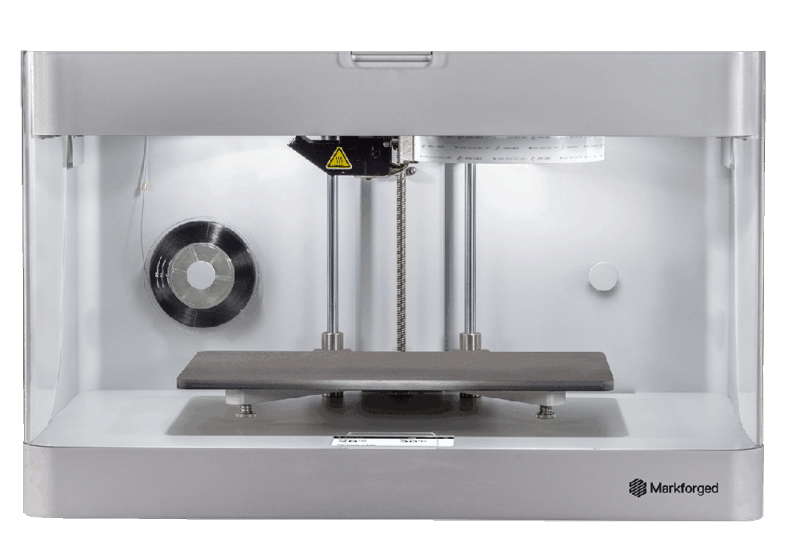

Industrial Composite Printers

A complete line of machines made to create functional parts. industrial-grade 3D printers are equipped with precision construction and a connected platform, which ensures continuous improvement in performance.

FX10:

FX10 is the first industrial metal and composite 3D printer. The result of years of engineering innovation, it builds on the legacy of the Markforged X7 and Metal X to deliver durable, high-precision tools and fixtures—fast and efficiently—right to your factory floor.

Download Datasheet

FX20:

A large format 3D printer is capable of using ULTEM™ Filament to create big, strong, and high-temperature parts usable from the factory floor.

Download Datasheet

X7:

The X7 3D printer creates strong carbon fiber-reinforced parts in hours, with properties like machined aluminum. It's ideal for producing functional parts with impressive strength, flame, chemical resistance, and energy absorbance.

Download Datasheet

Additive Application Case Study:

Soft Jaws

66%

FASTER

Lead time went from

3 weeks → 1 week

75%

SAVINGS

Cost went from

$6,000 → $1,500

Easy to Design

Create conformal, non-marring grip surfaces tailored to the part geometry.

Save Time & Money

Eliminate lengthy CNC processing; print soft jaws overnight.

Specialized Applications

Build custom workholding for complex or low-volume jobs.

Desktop 3D Printers

Professional desktop 3D printers designed for versatility to test design concepts and build strong end-use parts.

Mark Two:

The best desktop printer for stunning prototypes, tools, high-performance end-use parts, and replacement parts.

Download Datasheet

Onyx Pro:

The enhanced desktop printer for stunning prototypes, tools, and production parts.

Download Datasheet

Additive Application Case Study:

Functional Prototyping

93%

FASTER

Lead time went from

156 hrs → 12 hrs

99%

SAVINGS

Cost went from

$800 → $10

Print On-Demand

Test form, fit, and function quickly with on-demand printed parts.

Save Money

Create functional prototypes in-house with minimal labor and no tooling.

Iterate Faster

Shorter lead times speed product development to market.

Print a Markforged Custom Part

Materials: From Plastics to Stainless Steel:

Markforged printers support a range of materials, including plastics, carbon fiber, and stainless steel, enabling versatile applications across various industries.

3D Printing Services and Rapid Prototyping:

Ellison Technologies offers 3D printing services to help bring your product ideas to life quickly. Rapid prototyping capabilities allow for faster design iterations, improving communication and collaboration between design and engineering teams.

Use 3D printing to quickly manufacture at the point of need and achieve a faster time-to-market. With Markforged 3D printing, you can create jigs, tooling, fixtures, manufacturing aids, and end-use parts. Contact us to get your part 3D printed and see what it can do for your company.

Ready to learn more?

You’re passionate about your business. We’re passionate about fueling your success. Reach out today and let's start a conversation.

Get in touch with one of our GSC 3D Printing Experts directly: (866) 753-0631