TruPrint Series

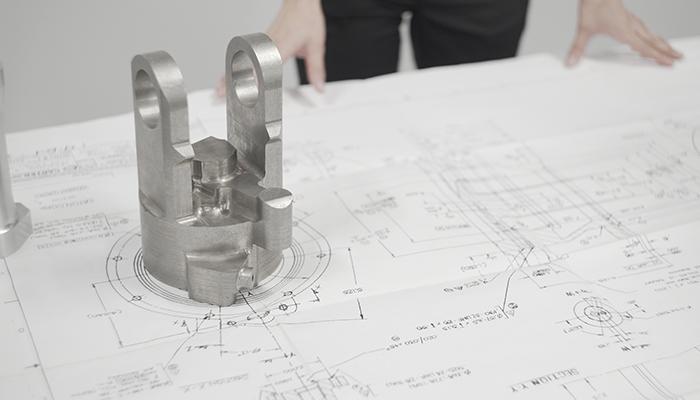

Utilizing 3D printing technology and as a leading manufacturer in laser technology, TRUMPF offers a diverse selection of additive production systems capable of delivering outstanding performance for your shop. TRUMPF’s TruPrint Series creates complex metal parts from metal powders bonded by lasers to create seamless parts in small to large batch quantities. Whether you need the TruPrint 3000 with its external part and powder management, the TruPrint 5000 for maximized series production, or the TruPrint 1000 for creating small parts with a compact footprint, there is an additive manufacturing solution to fit your needs.