Precision measurement is the foundation of successful manufacturing. Ellison Technologies offers advanced metrology equipment that not only verifies critical part dimensions but also drives productivity improvements through faster inspection cycles, reduced scrap rates, and enhanced quality control processes. Our comprehensive range of measurement solutions delivers the accuracy manufacturers demand and the efficiency your production floor requires.

Equipment Capabilities

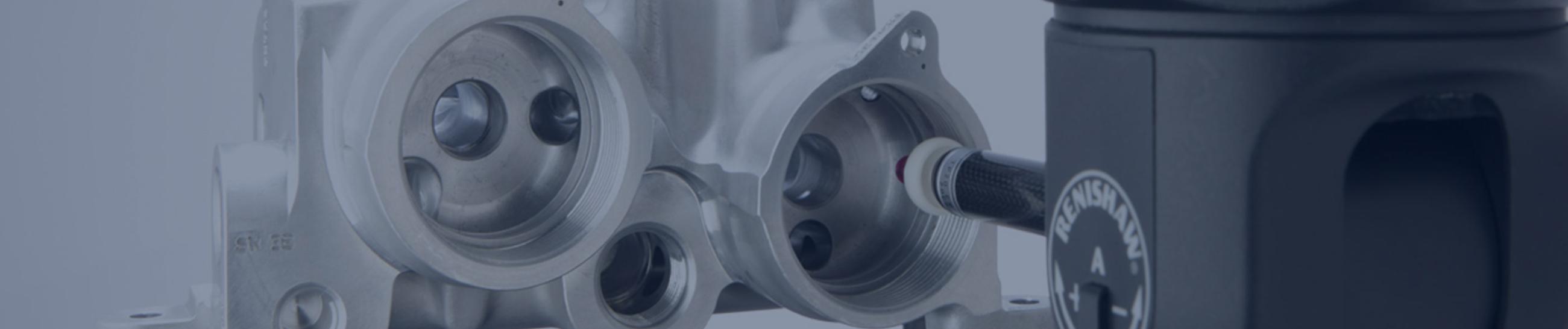

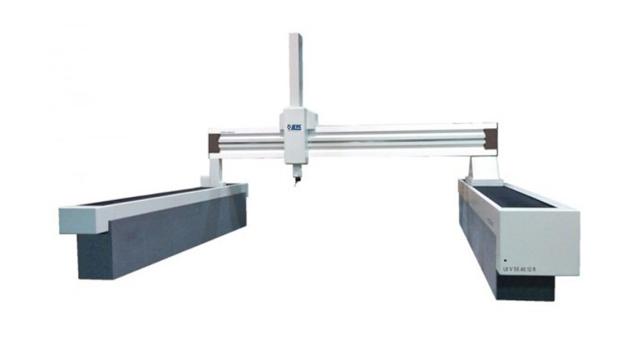

From basic dimensional verification to advanced coordinate measuring machines (CMMs), Ellison Technologies provides metrology solutions engineered for manufacturing environments. Our equipment delivers accuracies measured in microns while maintaining the durability needed for shop floor deployment. With both contact and non-contact measurement options, we deliver the right technology for your specific application—whether that's high-volume production inspection, complex part verification, or in-process monitoring systems that integrate directly with your CNC machines.

Manufacturing Benefits

Implementing advanced metrology solutions from Ellison Technologies delivers measurable advantages to your manufacturing operation:

- Reduce scrap rates by identifying dimensional issues before production runs

- Decrease inspection time with automated measurement sequences

- Improve part consistency through statistical process control integration

- Enhance quality documentation with comprehensive measurement reporting

- Accelerate first article inspection for faster production startups

- Enable lights-out verification with automated inspection systems

- Support ISO and industry certification requirements with traceable measurements

The LK Metrology complete range of premium bridge, gantry and horizontal arm coordinate measuring machines represent the ultimate in CMM technology.