CNC Machining for the Firearms Industry:

Achieving Precision, Accuracy, and Reliability.

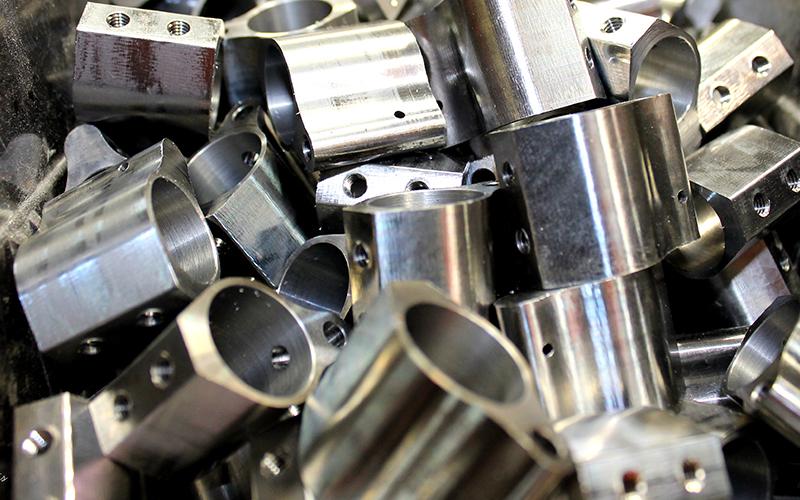

The firearms industry demands the highest levels of precision, reliability, and durability for components such as barrels, receivers, and trigger mechanisms. These parts are critical to ensuring the proper functioning and safety of firearms, whether for sporting, law enforcement, or military use. At Ellison Technologies, we provide CNC machinery tailored for the rigorous demands of firearm manufacturing. Our machines are designed to handle high-volume, tight-tolerance production while maintaining exceptional accuracy and surface finish, ensuring that every part meets the industry's stringent standards.

Key Applications:

Firearm Bodies & Slides

Parts: Pistol frames, rifle bodies, shotgun receivers, slides

Materials Used: Steel alloys, aluminum, polymer composites

Application Details: Ensures proper fit and functionality, critical for firearm performance and durability.

Recommended Machines: DNM Series, DVF Series, NHP Series

Bolt Carriers

Parts: Bolt carriers, carrier keys, gas rings

Materials Used: Heat-treated steel, stainless steel, titanium

Application Details: Precision machining for smooth cycling and reliable operation.

Recommended Machines: TT Series (e.g., 1300SYY, 1800SY, 2100SYY)

Cylinders & Guards

Parts: Revolver cylinders, hand guards

Materials Used: Stainless steel, aluminum alloys

Application Details: Requires precise machining to ensure rotation and protection.

Recommended Machines: PUMA 2600

Safety Locks & Firing Pins

Parts: Safety lock assemblies, firing pins, firing pin springs

Materials Used: Hardened steel, stainless steel, alloy steels

Application Details: Machined to ensure reliability and safe operation.

Recommended Machines: Lynx 2100LB

Triggers & Trigger Assemblies

Parts: Triggers, sears, hammer assemblies

Materials Used: High-carbon steel, stainless steel, alloy steels

Application Details: Machined to withstand mechanical stress and ensure smooth operation.

Recommended Machines: Lynx 2100LSYB, DNM Series

Accessories

Parts: Rails, sights, muzzle devices, magazine parts

Materials Used: Aluminum, steel, polymer composites

Application Details: Machined for functionality and aesthetic quality.

Recommended Machines: DVF 5000

Machines and Solutions:

Lynx 2100LB

– Turning Center

Key Features: High-speed, high-accuracy turning capabilities with excellent repeatability.

Ideal Applications: Small to medium-sized parts like firing pins, safety locks, and triggers.

Benefits: Precision turning operations for intricate features on smaller firearm components.

TT Series

– Multi-Tasking Machine

Key Features: Combining turning and milling in one platform, capable of complex machining operations.

Ideal Applications: Bolt carriers, carrier keys, and other components with cylindrical and complex features.

Benefits: Versatile and capable of reducing setup time while providing high accuracy.

DNM Series

– Vertical Machining Centers

Key Features: Versatile machining center with a high-speed spindle and superior rigidity.

Ideal Applications: Machining firearm bodies, slides, and receivers with tight tolerances.

Benefits: Ideal for high-volume production with precise dimensional accuracy and surface finishes.

DVF Series

– 5-Axis Machining Centers

Key Features: High-speed machining with 5-axis capabilities for complex parts.

Ideal Applications: Machining complex components like firing pins, bolts, and other accessories.

Benefits: Reduces cycle time and provides flexibility for machining detailed geometries.

NHP Series

– Horizontal Machining Centers

Key Features: High rigidity, precision, and spindle speeds for machining large and complex parts.

Ideal Applications: Firearm bodies, slides, and other components requiring tight tolerances.

Benefits: Superior chip removal and reduced cycle times for high-volume production.

Lynx 2100LSYB

– Turning Center

Key Features: Dual-spindle, Y-axis turning center for precision machining.

Ideal Applications: Triggers, trigger assemblies, and other small components.

Benefits: Increases productivity and reduces cycle times for complex parts.

Puma 2600

– Turning Center

Key Features: Robust turning capabilities for medium to large parts.

Ideal Applications: Revolver cylinders and hand guards.

Benefits: Ensures precision and durability for rotational components.

DNX

– Vertical Machining Center

Key Features: High-performance machining for large components.

Ideal Applications: Versatile use for various firearm components.

Benefits: Exceptional rigidity and accuracy for heavy-duty machining tasks.

Customer Stories & Educational Articles

Precisionmatics

Precisionmatics

With over 85 CNC machines in their shop, Precisionmatics finds productivity and success with their wide range of Doosan Machine Tools machining aerospace, firearms, medical, airplane and helicopter components.

Zermatt Tool

Zermatt Tool

"We put DN Solutions to the test and they passed with flying colors"

-Eric Stieb

5 Things You Need to Know About the 5-Axis DVF Series from DN Solutions

5 Things You Need to Know About the 5-Axis DVF Series from DN Solutions

If you’re sniffing around for a 5-axis CNC machine that backs up its boasts, here’s everything you need to know about the DVF Series.

Increasing Profitability and Productivity with the Doosan PUMA TT

Increasing Profitability and Productivity with the Doosan PUMA TT

Diversified has worked with the Ellison Cleveland team for nearly 20 years benefiting from the full-service support including machine service, applications engineering, and parts replacement.

Learn More About How Ellison Can Help You Succeed in the Firearms Industry

- Precision and accuracy for high-quality firearm components

- High-speed, multi-tasking machines to reduce cycle times

- Tailored solutions for both small and large production volumes

- CNC machinery designed for tight tolerances and complex geometries

- Improve your manufacturing process with advanced automation and 5-axis capabilities