FAQ Section

How does the Lynx 2100LSYB improve part throughput and quality?

By integrating Y-axis milling, live tooling, C-axis contouring, and sub-spindle machining in a single cycle, the Lynx 2100LSYB eliminates redundant setups and material handling. This increases productivity while reducing part variation and handling errors.

What makes this machine automation-ready?

It includes a part catcher, conveyor, barfeed interface, and optional high-pressure coolant systems. These features support lights-out machining and seamless integration with robotic automation for continuous, unattended production.

What types of parts is this machine ideal for?

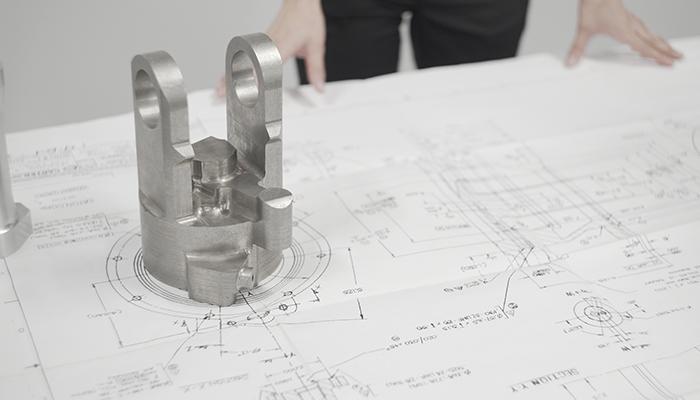

The Lynx 2100LSYB is ideal for complex, multi-operation parts such as precision hydraulic components, medical fittings, automotive shafts, and aerospace parts that require back-side operations, off-center drilling, or milled flats.

Is it user-friendly for shop-floor operators?

Yes. The FANUC 0i-Plus control with EZ Guide i programming makes it easy for operators to program tool paths without full G-code knowledge. Tool load monitoring and an iHMi touchscreen streamline diagnostics and tool management.

How is long-term reliability maintained?

With heavy-duty roller-type linear guides, robust cast slant-bed construction, and intelligent safeguards like disturbance torque detection and high-precision ball screws, the Lynx 2100LSYB is built to endure continuous, high-load operation without loss of accuracy.