Opportunities with 5-Axis DVF 5000

Why should customers come to you instead of your competition? Good question. Pep Manufacturing, a family-owned CNC job shop located in Mentor, Ohio, has found a way to stand out and gain market share: with a little help from Ellison Technologies and Doosan.

They’ve been serving their customers with quality machining since 1997, and most of their business is high-mix/low-volume work for CNC tooling, hydraulic, aerospace and railroad customers. The combination of machine tools on the floor has always been pretty balanced between turning machines and vertical mills with 4th axis tables.

Joe Pepka, Sr., VP of production and CNC programming, has worked with Ellison Technologies for over 30 years. So, when it was time to think about the future, there was no doubt in his mind who to call. He has Nick Sowards, Sales Manager at Ellison, on speed dial.

Finding the Differentiator

First, Pepka stopped to take a look at his company to see where it was going. Most shops in the area had the same mix of equipment, and Pepka wanted to shake things up and stand out from the crowd. “We wanted to take the company in a new direction and offer capabilities that the competition just couldn’t match. I thought a 5-axis machine was the way to achieve that goal,” he said.

First, Pepka stopped to take a look at his company to see where it was going. Most shops in the area had the same mix of equipment, and Pepka wanted to shake things up and stand out from the crowd. “We wanted to take the company in a new direction and offer capabilities that the competition just couldn’t match. I thought a 5-axis machine was the way to achieve that goal,” he said.

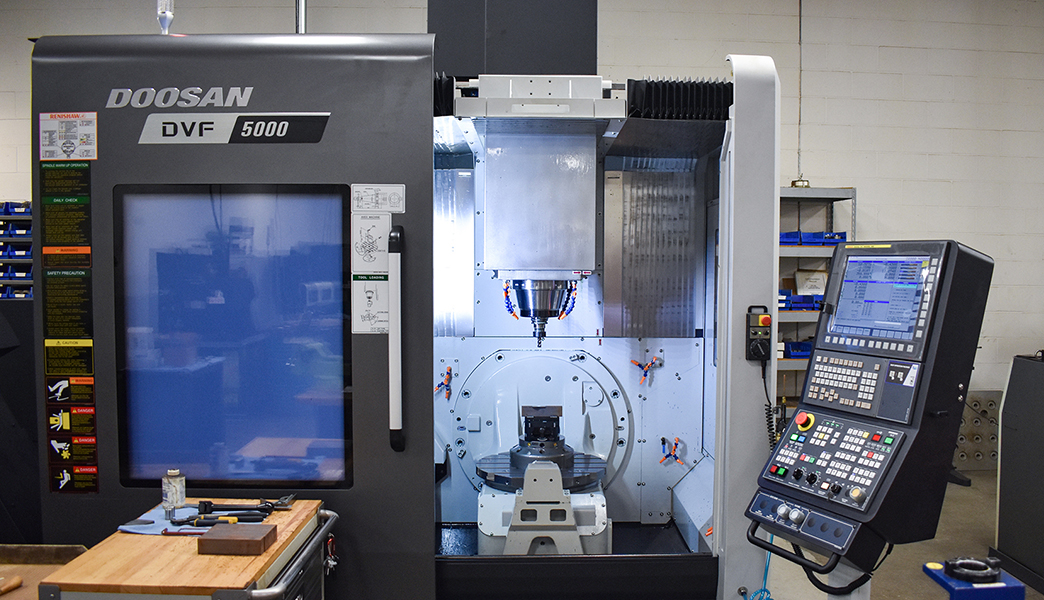

After consulting with Sowards, Pepka purchased a Doosan DVF 5000 full 5-axis vertical machining center with a 60-tool magazine, an 18,000 r/min spindle, high-pressure through coolant and a 500mm rotary table size. “The DVF 5000 uses the same control as our Lynx machines, so it was easy to learn the basics,” Pepka said. “But once you start flipping the table and rotating every which way, things can get complicated, so I rely on GibbsCAM software to help me with the programming.”

5-Axis Business Bump

Pep Manufacturing’s business has grown quickly. Pepka is now asking his clients for models of 5-axis parts instead of prints. He imports the models into GibbsCAM, extracting geometry and defining tool paths for that geometry. “Now we can handle the complex work we have always wanted to machine,” Pepka said. “The sky’s the limit with the DVF 5000.”

For example, Pep Manufacturing is heavily involved with machining parts for a major toolmaker. “In the past, we had to quote on jobs based on the capabilities of our 3- and 4-axis machines”, Pepka said. “With the DVF 5000, we can handle all the work in one setup.” The company also wants to take advantage of the 5-axis machine’s contouring capabilities by going after bids for mold parts.

Saving the Day

The DVF 5000 is currently taking on overflow work for a firearms component manufacturer. The customer had a bunch of special purpose machines turnkeyed for the part (a pistol slide), but with demand being so high, they couldn’t keep up. The capabilities of the DVF 5000 enabled Pep Manufacturing to step up and lend a hand.

The part starts from a block of 4140 steel that has 40-44 Rockwell hardness. Currently the machining is done in two operations, both on the DVF 5000. Using Jergens 5-axis work holding, the cycle time for a complete part is around one hour.

The overflow work started as a 40-piece run off, but Pep Manufacturing is now handling 100-piece runs. According to Pepka, “The client was really impressed and so pleased with the results that we are now being considered for the company’s prototype work as well.”

Ellison Relationship

Pepka has always been loyal to Ellison and its team. “As for service, they are top notch,” he said. “You couldn’t ask for a better service group.” Pepka says they even check in with his operators when he is on vacation just to make sure everything is running smoothly during his absence. Now that’s service. “I have no need to shop around because I am very happy with the relationship I have. They’re more like family than business partners,” he said.

If you’re thinking of expanding the capabilities of your shop, or if you need to replace some older equipment with something that lasts, contact us and get the renowned Ellison service that Pep Manufacturing can’t work without.