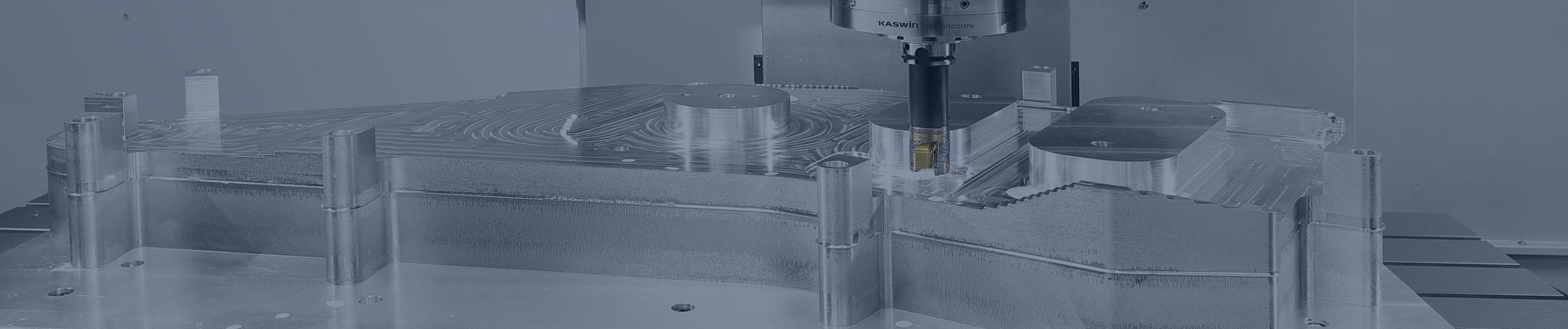

What Are 5-Axis CNC Machining Centers?

5-axis CNC machining centers represent the pinnacle of precision manufacturing technology, enabling manufacturers to machine complex parts with unprecedented accuracy and efficiency. Unlike traditional 3-axis machines that move along X, Y, and Z axes, 5-axis systems add two rotational axes (A and B), allowing the cutting tool to approach the workpiece from virtually any angle.

Key advantages of 5-axis machining include:

- Single-setup machining - Complete complex parts without repositioning

- Superior surface finish - Consistent tool orientation eliminates witness marks

- Faster cycle times - Simultaneous multi-axis movement reduces machining time

- Enhanced precision - Eliminates cumulative positioning errors from multiple setups

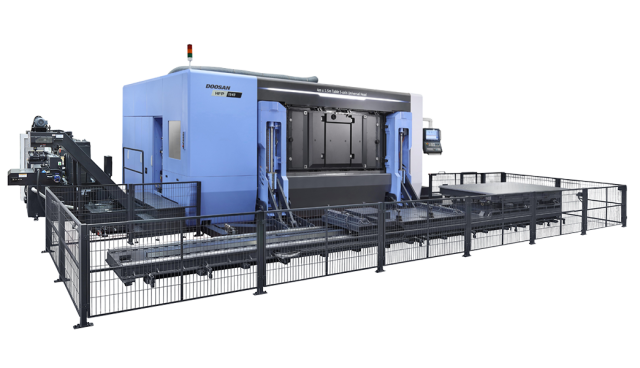

Machine Tool Centers

DN Solutions has a proven record of successful machine installations in the U.S. market for over 30 years. It offers a diversified product line, with choices ranging from small lathes and mills to heavy duty machining centers to very large double column and boring mills.

DNM 5AX Series

DVF Series

VCF 5AX Series

VC 5AX Series

DHF Series