Darmark Corporation, based in Poway, California, has delivered high quality machined components for the aerospace, medical, semiconductor, transportation, and energy industries for over 40 years. As an ISO9001:2015 and AS9100D certified company, Darmark Corporation is constantly seeking to expand their capabilities, productivity, and profitability. Darmark currently runs 7 Doosan Machine Tools machining and turning centers with their most recent addition of the Doosan DVF 5000 equipped with the Doosan Robotics M1013 cobot.

Watch this video to find out why Darmark trusts the reliability and support of Doosan and Ellison Technologies as Darmark’s 5-Axis Milling Supervisor, Kyle Christensen, discusses increased productivity, performance and reliability, and the service and support from Ellison Technologies.

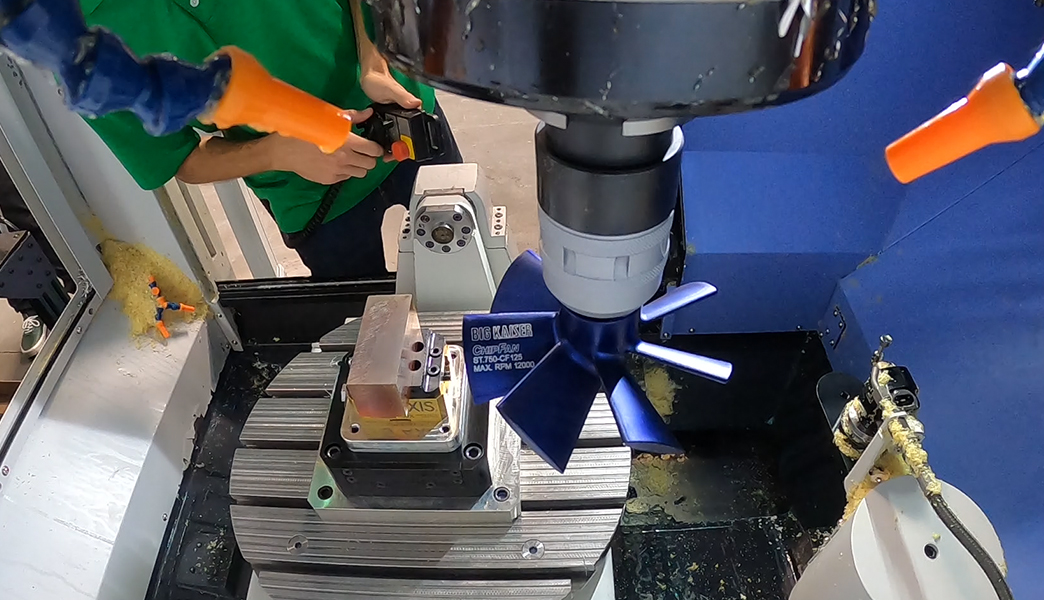

Ventilating Need with Doosan

With the nationwide shortage of ventilators, Darmark received a request for ventilator components and needed to increase productivity to meet the production requirements. With over 14 years of experience working with Ellison Technologies, Darmark reached out to get the right machine to fulfill their needs.

With the nationwide shortage of ventilators, Darmark received a request for ventilator components and needed to increase productivity to meet the production requirements. With over 14 years of experience working with Ellison Technologies, Darmark reached out to get the right machine to fulfill their needs.

After consulting with Ellison Technologies’ BlueChip Advanced Manufacturing Group and 5-axis Product Manager, Chris Wood, for the right solution; the Darmark team selected the Doosan DVF 5000 and added automation capabilities with a Doosan Robotics cobot.

“With this new DVF we’ve seen excellent quality. Cycle times are shorter, tool changes are way faster, chip to chip is great, the acceleration of this machine is incredible.” – Kyle Christensen, 5-Axis Milling Supervisor, Darmark Corporation

The simultaneous five axis DVF 5000 boasts incredibly productive features including an 18,000 rpm, 29.5 hp spindle, 60 slot ATC, 1,575 ipm rapids, and rigid linear roller guides. The Doosan Robotics cobot features a 51.2” reach, 22 lb. payload capacity, and 6 high sensitivity torque sensors in each joint for speed, precision, and safety. With these two components combined, Darmark is able to achieve done-in-one machining with lights out automation.

Reliability to Productivity

Darmark began seeing the productive results of DN Solutions mills and lathes with their first Lynx 220LC turning center in 2013 and DNM 5700 vertical machining center in 2018. Satisfied with their performance, Darmark acquired two PUMA GT2600 horizontal lathes in 2019 followed by an NHP 4000 horizontal machining center, another DNM 5700, and a DNM 4000 in 2020. The reliability of DN Solutions machines was further enhanced by the service and support from the Ellison Technologies team.

“[Ellison Technologies] service is great, everything from sales all the way down to service to phone support. Anything you could ever want; their responses are great.” – Kyle Christensen, 5-Axis Milling Supervisor, Darmark Corporation

Ellison Technologies offers full-service support including preventative maintenance, machine service and repair, spindle repair, parts and installations, training, and turnkey applications.

See why Darmark continues to trust DN Solutions and Ellison Technologies by watching the video above.