Are you Ready for Some… 5-Axis?

Bringing the Best Together for High Performance Machining

It’s football season in America, and if you’re anything like us, you’re spending hours a week watching games and setting your fantasy lineup. We’re all dreaming of more players that have that super-human combination of power, strength, speed, and smarts needed to push your team to victory.

Have you ever dreamt of a machine that had an unreal combination of attributes? One that had the power, strength, speed, and smarts to combine 5-axis milling and turning to make quick work of complicated large parts in aerospace, oil field, and mold and die industries?

The C Series from HELLER is just that machine. Game on.

The ABC’s and 123’s of High Performance Combination Milling & Turning

Before we jump into the amazing attributes of the C Series, let’s get some quick definitions out of the way:

- C: the C in “C Series” stands for “combined,” as in combined milling and turning

- CP: the C Series variant with an integrated pallet changer, ideal for higher volume production runs. We offer four versions of the CP with 500, 630, 800, and 1000 mm pallet options.

- CT: the C Series variant with table loading, great for small batch production runs. We offer two versions of the CT with 630 and 800 mm pallets.

- HSK63T: three high speed spindle options with up to 16,000 RPM

- HSK100T: four high power spindle options with up to 1,146 Nm (845 ft lbs) of torque

- 5th Axis: swivel and tilting head options make quick work of complex parts

- BFD: this machine is a Big Freakin’ Deal that will level up your shop’s capabilities in an instant

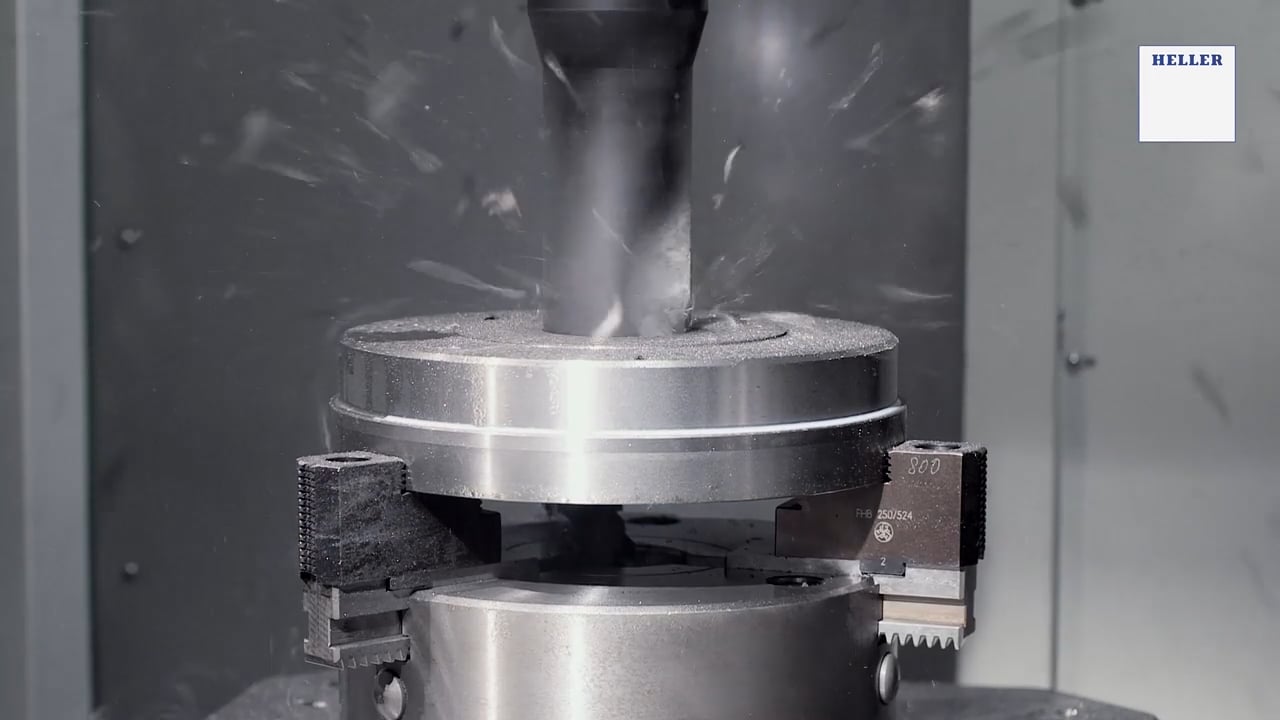

Watch the C Series in Action

Attribute 1: Strength and Power of an Offensive Lineman

The most ambitious cuts, precision surface finishes, and handling of workpieces up to 4,000 kg (8,800 lbs) can’t be done without a rigid machine structure. The C Series merges a machine bed optimized for rigidity and a mass-reduced column to ensure stability for even the most aggressive applications.

The DDT (Direct Drive Turning) rotary table turns huge parts with its spindle motor that delivers up to 6,560 Nm (4,840 ft lbs) of torque. And like all HELLER machines, the C Series is built for precision jobs in production machining environments. This big boy is designed to be continuously in the game and not on the bench.

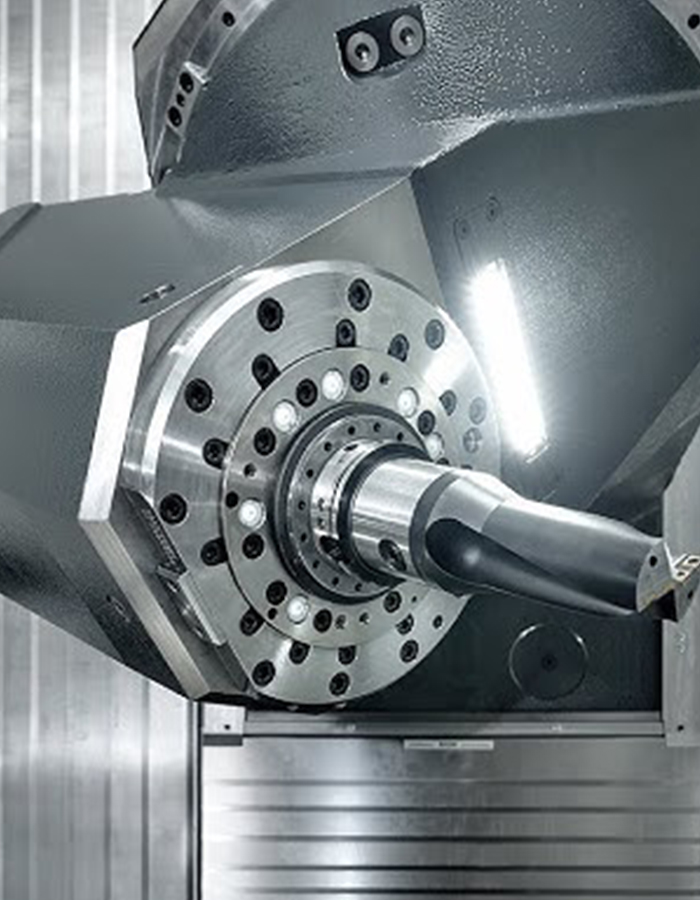

Attribute 2: Speed and Precision of a Wide Receiver

Wouldn’t it be great to see a 325-pound lineman run a perfect go route and come down with the ball? That’s the type of speed and precision that the C Series mashes up with its beefy frame.

Optimized kinematics help the C Series move in ways that have to be seen to be believed. Linear axes with roller guides driven by ball screws combined with direct absolute measurement systems (glass scales in linear axes) guarantee the highest precision and positioning possible. And with fast milling spindles, rapid chip-to-chip times, and the Siemens SINUMERIK 840D control, speed is built into every aspect of this unique machine.

Attribute 3: Smarts of a Seasoned Coach

If you’ve ever worked with a HELLER machine, you can feel how much engineering experience has gone into these elite-class machining centers. Whether at the workpiece setting station, during tool loading, programming, or maintenance, your comfort, safety and, above all, the productivity of your manufacturing operations are front and center.

And like the best coaches, the C Series is surrounded by other high performers: optional pallet management system for multiple set-ups, high-productivity automation solutions, and centralized tooling automation.

Bonus Attribute: The Ellison Team on Your Side

There is perhaps no dealer partner in all of North America better equipped to help you make more parts, more money, and more for the legacy you’re building.

If you have parts and applications that require the kind of high performance combination milling and turning that the HELLER C Series brings, reach out to us for a deeper look into our playbook.