FAQ Section

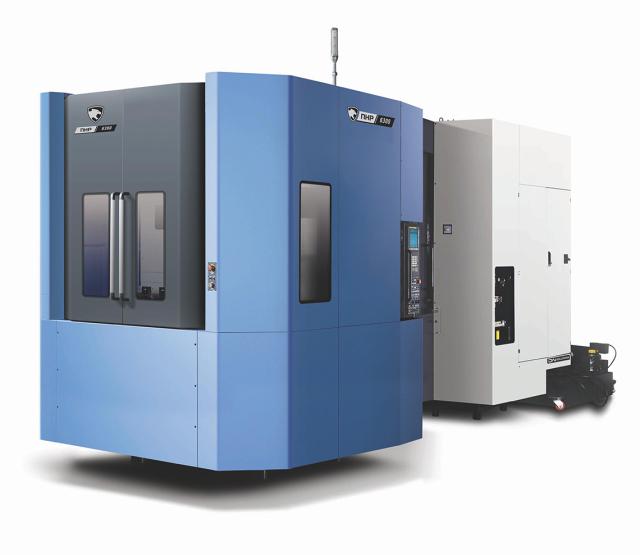

What type of cutting environments is the NHP 6300 designed for?

The NHP 6300 is designed for a combination of heavy-duty cutting and high-speed machining, along with high precision over a wide range of applications. It is engineered to maximize productivity with faster speeds and enhanced precision, making it ideal for demanding applications.

How does the NHP 6300 achieve high torque at low RPMs for roughing operations?

The machine utilizes a powerful built-in spindle motor with a dual-wound, "virtual gearbox" design. This system allows for two virtual gear ranges and generates 420 Nm (310 ft-lbs) of torque in the low spindle range, providing excellent performance for heavy roughing cuts.

What features ensure the stability and accuracy of the machine structure?

The stability is ensured by the use of a rigid, one-piece casting made from fine grain Meehanite cast iron, which is heavily ribbed to withstand deformation under heavy cutting loads. All axes employ Linear Roller Motion Guides (53 mm / 2.086"), which are heavy-duty and widely spaced for optimal rigidity and force distribution. Additionally, the spindle uses a CAT 50 Big Plus system, which achieves maximum rigidity through simultaneous taper and flange contact.

Can the NHP 6300 accommodate large fixtures or tombstones?

Yes, the machine's table area (630 mm x 630 mm) can accommodate a maximum part size of 1,050 mm (41.3") in diameter and 1,350 mm (53.1") in height (when no hydraulic interface is present). The machine also includes qualified edge locators to aid in setting up fixtures or tombstones.

What control systems are in place to prevent tool damage and optimize cutting time?

The NHP 6300 includes two key systems: the Adaptive Feedrate Control (AFC) and the Tool Load Monitoring System (TLM). AFC adjusts the programmed feedrate based on the monitored spindle load, compensating for severe axis overload or detecting air cutting. The TLM continually checks the load on the axes and spindle motors, allowing operators to set limits for wear and breakage conditions, which triggers an alarm and stops operation if abnormal loads are detected.