FAQ Section

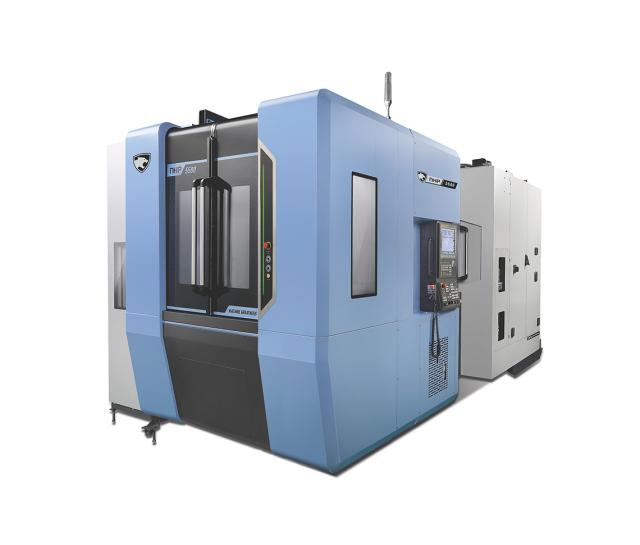

What structural elements ensure the NHP 5500 maintains high rigidity during heavy cutting?

The machine is constructed with a one-piece bed made from fine grain Meehanite cast iron. All axes utilize Large Linear Roller Guides (53 mm), which are 3 times more rigid and have 2 times more life compared to common ball bearing guide types, optimizing weight and force distribution for superior cutting performance and stability.

How does the NHP 5500 2nd Generation mitigate thermal distortion for long cycle times?

Thermal effects are minimized through several standard features: cooling through the center of the ball screw shaft, the ball nut, and support bearings. The system also uses Smart Thermal Monitoring software with hardware sensors to compensate the Z-axis for thermal growth. Additionally, a coolant chiller maintains a consistent coolant temperature, which helps eliminate thermal growth effects.

What is the efficiency rating of the Automatic Tool Changer (ATC) and Pallet Changer?

The standard 60-tool, pot type double arm ATC provides a reliable tool-to-tool change time of 1.7 seconds (for tools under 8 kg). The standard rotary shuttle type Automatic Pallet Changer (APC) has a pallet change time of 12 seconds.

What safety features are included to protect tooling and parts during operation?

The machine includes a Tool Load Monitoring System which continually checks the load on the spindle and axis motors, allowing high/low limits to be set for wear and breakage. It also features Adaptive Feedrate Control (AFC), which monitors spindle load and initiates a “Feed Hold” condition and alarm state in the event of severe axis overload or catastrophic tool failure.

What is the primary benefit of the Big Plus Spindle System used on the NHP 5500?

The Big Plus Spindle System utilizes the CAT 50 standard and surpasses other spindle concepts by providing simultaneous taper and flange contact between the machine spindle and tool holder. This maximum rigidity is achieved because the tool is pulled in until the tool flange touches the spindle face, ensuring superior cutting performance.