CNC Machining for the Energy, Oil, and Gas Industries:

Delivering Precision, Durability, and Efficiency for Energy Manufacturing

The energy, oil, and gas industries are driven by the need for rugged, high-performance components that can withstand extreme conditions. From exploration to production, companies rely on advanced manufacturing solutions to produce critical parts with unparalleled precision and durability. Ellison Technologies provides machining equipment designed to meet these demands, whether you're producing high-stress turbine components, drilling parts, or subsea equipment. Our machines deliver superior results, enabling manufacturers to meet the challenges of high-volume, high-precision production with maximum efficiency and reliability.

Meeting the Needs of the Energy Industry

Applications Include:

- Turbines

- Drilling and casing pipe components

- Valves and fittings

- Subsea equipment

Manufacturing Challenges:

Energy manufacturers face unique challenges, such as machining large, heavy components with tough materials while maintaining strict tolerances and efficiency.

Solutions We Offer:

Our advanced machine tools and automation solutions are tailored to overcome these challenges, enabling increased productivity and reduced operational costs.

Tailored Machining Solutions

Drilling & Casing Pipe Parts

Ellison Technologies provides machining solutions for critical drilling and casing components, ensuring strength, precision, and durability.

Key Products: Drill pipes, collars, casing pipes, and couplings

Recommended Machines: NHM Horizontal Machining Centers, DBC Boring Machines

Fluid Control System Parts

Machining wellhead parts, BOP components, and fracture pump parts require exceptional precision and reliability.

Key Products: Valves, bodies, rams

Recommended Machines: PUMA SMX Multi-Tasking Machines, VC 630/5AX 5-Axis Machining Centers

Drilling Equipment

From drill bits to stabilizers and reamers, our solutions deliver superior performance for the energy sector’s most demanding applications.

Key Products: Drill bits, stabilizers, shock subs, and reamers

Recommended Machines: PUMA Turning Centers, VCF Series Vertical Machining Centers

Machines and Solutions

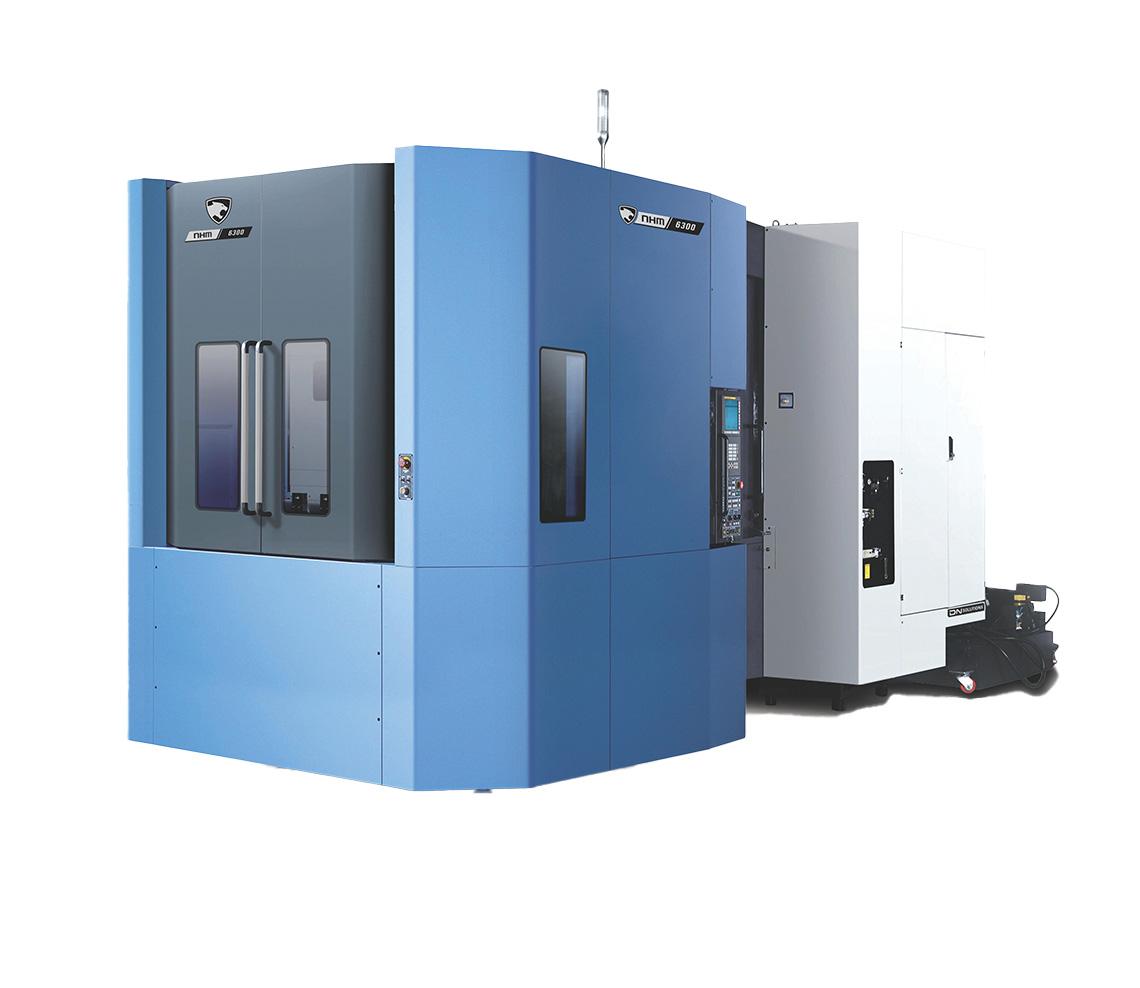

NHM Series

– Horizontal Machining Centers

Key Features: High-torque spindle and large work envelope for heavy-duty cutting.

Ideal Applications: Casing pipe machining, large valves, and turbine components.

Benefits: Exceptional rigidity and power for handling tough materials like stainless steel and titanium.

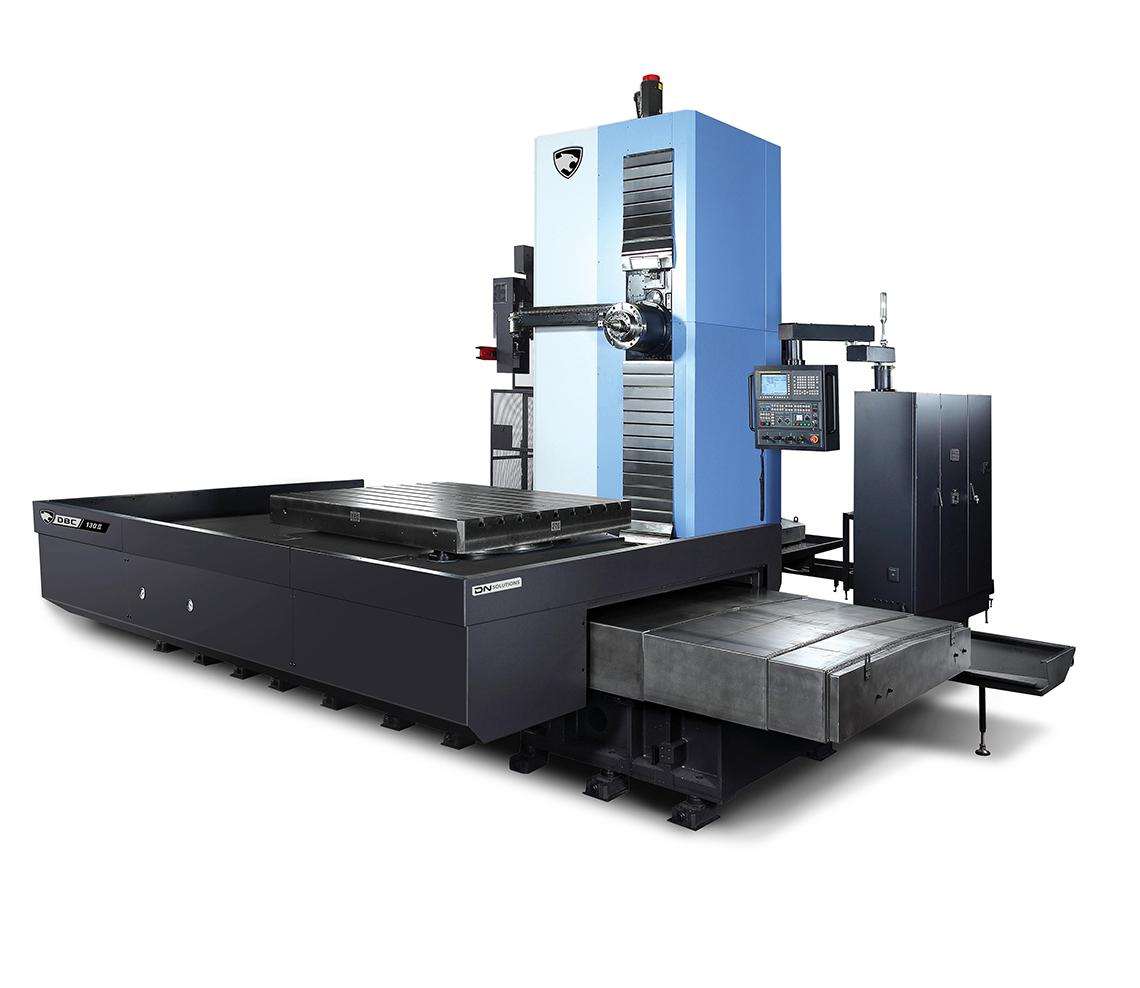

DBC Series

– Boring Machines

Key Features: High-precision boring and drilling capabilities with extended bed lengths.

Ideal Applications: Drilling pipe couplings, wellhead parts, and other long components.

Benefits: Maximize productivity with specialized attachments for threading and complex geometries.

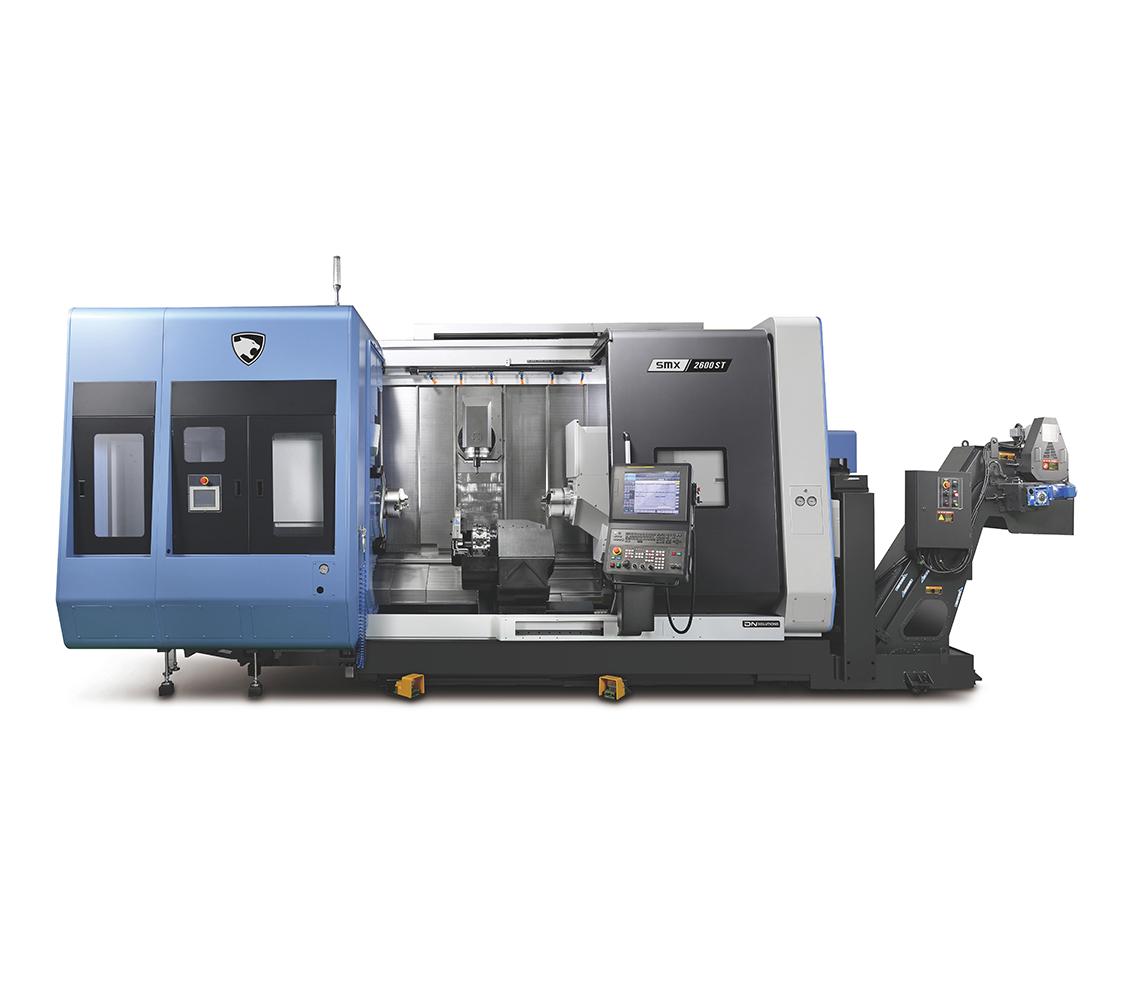

PUMA SMX Series

– Multi-Tasking Machines

Key Features: Turning, milling, and Y-axis capabilities in one platform.

Ideal Applications: Drilling equipment, reamers, and stabilizers.

Benefits: Reduce setups and increase accuracy for intricate part machining.

VC 630/5AX Series

– 5-Axis Machining Centers

Key Features: Compact design with full 5-axis machining capabilities.

Ideal Applications: Angular and contoured fluid control components like valves and fracture pump parts.

Benefits: Improved cycle times and precision for complex geometries.

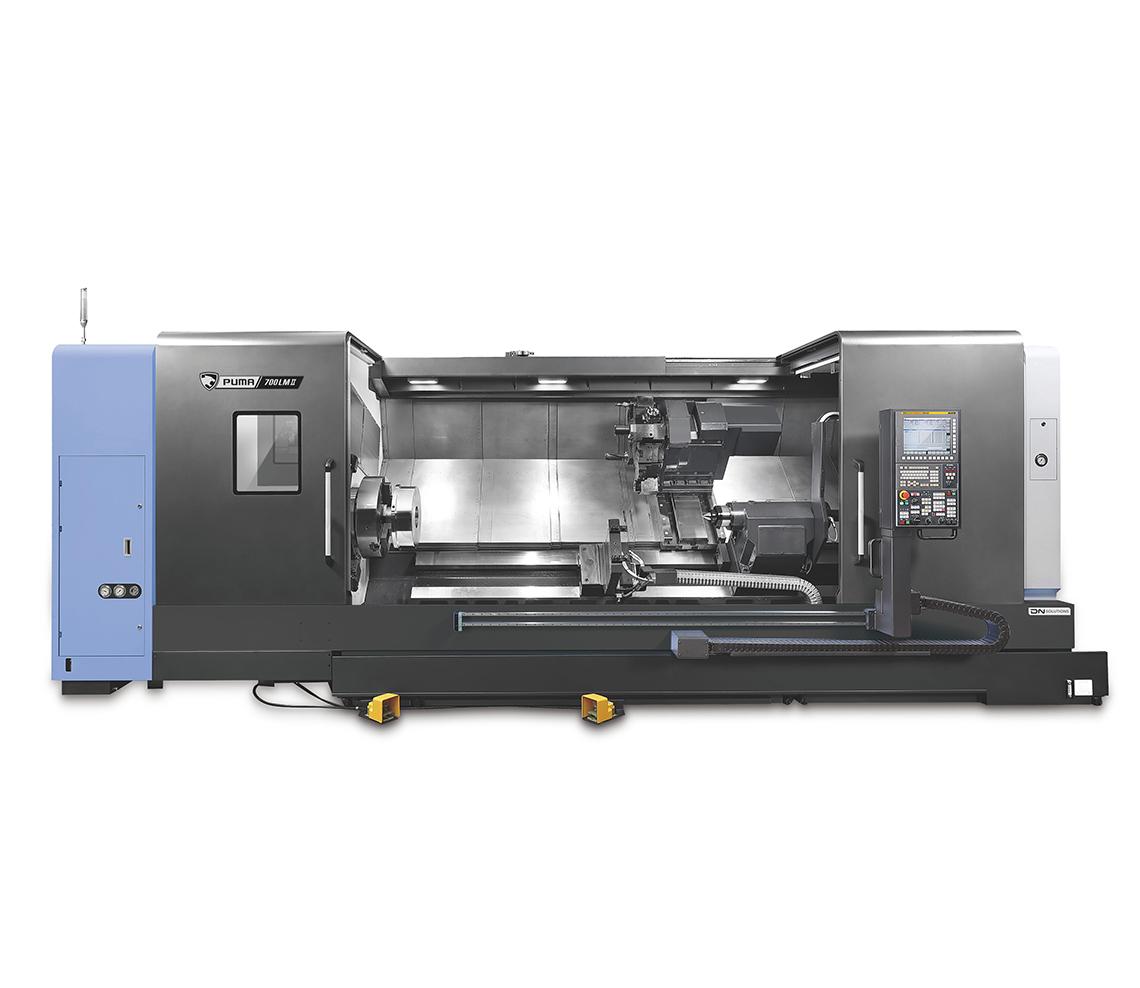

PUMA 700LY

– Large Turning Centers

Key Features: Long bed length, steady rests, and tailstock for large cylindrical parts.

Ideal Applications: Tubing pipes, rotary subs, and Kellys.

Benefits: Increased stability and repeatability for long, heavy workpieces.

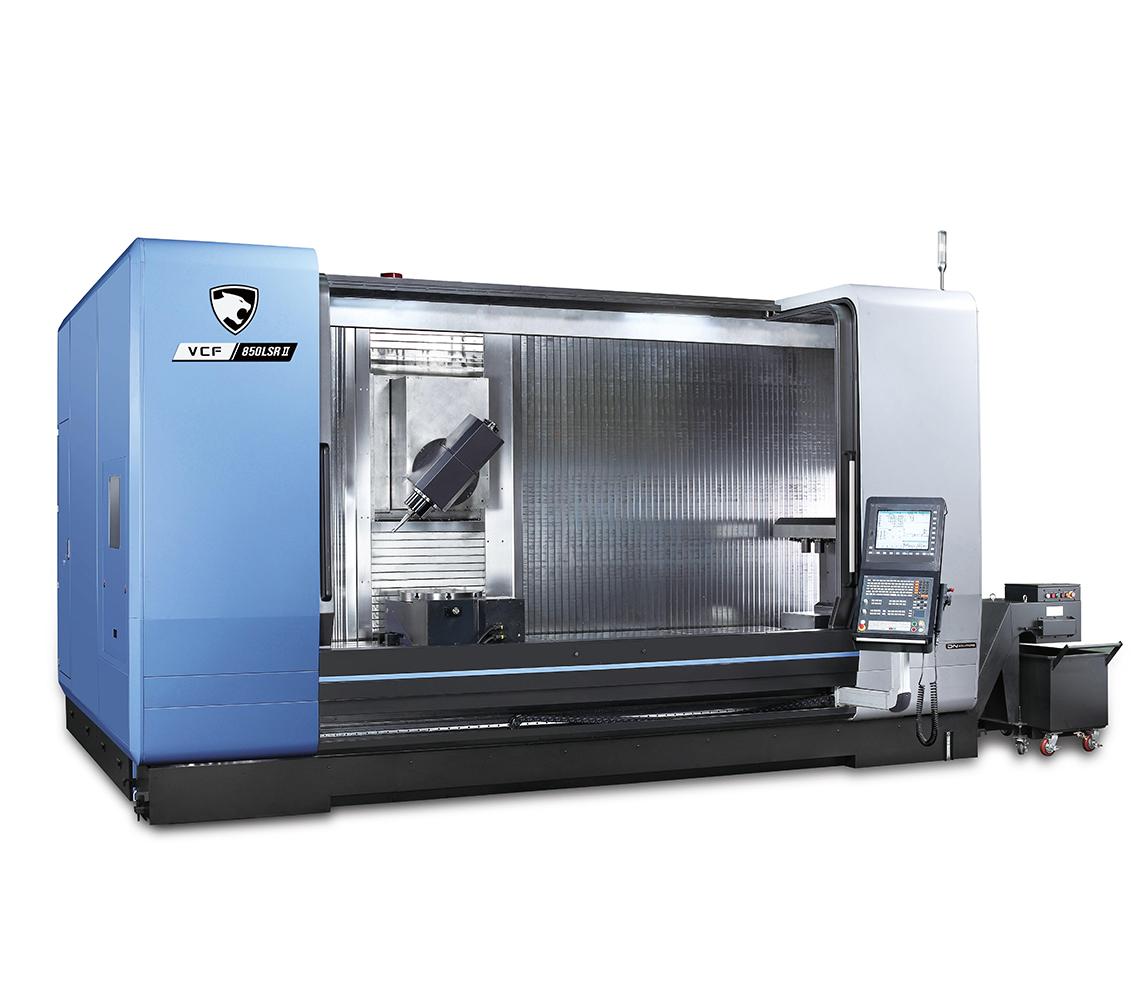

VCF Series

– Vertical Machining Centers

Key Features: Multi-purpose capabilities for drilling, milling, and surface finishing.

Ideal Applications: Drill bits, casing components, and subsea parts.

Benefits: Versatility for both high-precision and high-volume production.

Ready to Optimize Your Energy Manufacturing? Take the Next Step.

Ellison Technologies is here to support your energy and oil/gas manufacturing needs with tailored solutions designed for precision, performance, and reliability.

- Reduce setup times with multi-tasking machines.

- Handle tough materials with heavy-duty machining.

- Achieve tight tolerances for critical parts.

- Boost productivity with automation.

- Simplify processes with turnkey systems.