FAQ Section

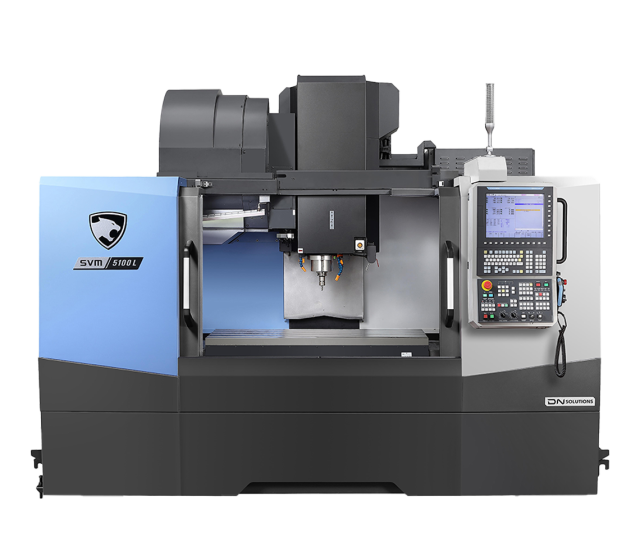

What specific industries and materials is the SVM 5100L optimized for?

The SVM 5100L vertical machining center was developed to meet the increased demand for machining of Aluminum die-castings in both the Automotive and IT industries. It can also be used for general-purpose light duty machining of steel parts.

How does the SVM 5100L ensure spindle rigidity and precision?

The machine utilizes the Big Plus Spindle system (CAT 40), which provides maximum rigidity through simultaneous taper and flange contact between the machine spindle and the tool holder. Additionally, the spindle features rigid tapping and is supported by an oil jacket chiller to reduce thermal effects.

What is the benefit of the Adaptive Feedrate Control (AFC) system?

Adaptive Feedrate Control enables the Machining Center to monitor the amount of spindle load a tool is generating during a cut, and then increase or decrease the programmed feedrate to compensate. It is useful for minimizing wasted cycle time by detecting air cutting and will trigger a "Feed Hold" condition if a catastrophic tool failure or severe axis overload occurs.

What are the travel capabilities and maximum load capacity of the SVM 5100L?

The machine offers 1,270 mm (50") of X-axis travel and 510 mm (20.1") of Y and Z-axis travel. The table size is 1,320 mm x 510 mm (51.96" x 20.1"), supporting an allowable table load of 800 kg (1,764 lbs).