DNM Series

The DNM Series delivers the most value for your investment as the best-in-class vertical machining center fully equipped with the most standard features built-in. This powerfully productive machine features a BIGPLUS spindle, dual chip augers, FANUC 0i-M controls with DN Solutions (formerly Doosan Machine Tools) Easy Operation Package (EOP), through-spindle coolant, spindle chiller, and more. Get the machine that will give you the power to MAKE MORE.

-

Rapid Traverse Z-axis24 m/min (945 in/min)

-

Travel Distance Y-axis762 mm (30 in)

-

Travel Distance Z-axis650 mm (25.6 in)

-

Rapid Traverse X-axis30 m/min (1181 in/min)

-

Rapid Traverse Y-axis30 m/min (1181 in/min)

-

Travel Distance X-axis2,160mm (85.03)

-

Table Size1630 x 760 mm (64.2 x 29.9 in)

-

Max Load1500 kg (3306 lbs)

-

Spindle to Table Distance200 - 850 mm (7.9 - 33.5 in)

-

Speed8000/10000 rpm

-

Power22/26 kW (29.5/35 Hp)

-

Torque165.5/353.3 Nm (122/260.6 ft-lbs)

-

ShankBIG PLUS CAT50

-

Changer Capacity30

-

Max Diameter125/220 mm (4.9/8.7 in)

-

Max Length350 mm (13.8 in)

-

Length4000 mm (157.5 in.)

-

Height3373 mm (132.8 in.)

-

Width2986 mm (117.6 in.) + 1323 mm (52.1 in.)

-

Weight15,300 kg (33,730 lbs)

Explore the DNM Series Lineup

-

DNM 4000

Spindle Taper: CAT 40

Spindle RPM: 12,000 RPM

X Axis Travel: 20.5"

-

DNM 4500 4th GEN

Spindle Taper: CAT 40

Spindle RPM: 8,000 RPM

X Axis Travel: 31.5"

-

DNM 4500S 4th GEN

Spindle Taper: CAT 40

Spindle RPM: 15,000 RPM

X Axis Travel: 31.5"

-

DNM 5700 4th GEN

Spindle Taper: CAT 40

Spindle RPM: 8,000 RPM

X Axis Travel: 41.3"

DN Solutions DNM 750/50L II

The DN Solutions DNM 750/50L II is a high-performance vertical machining center designed specifically for precision machining of medium to large workpieces. Featuring an expansive X-axis travel of 2,160mm (85.03"), this powerful machine delivers the capacity, rigidity, and precision required for demanding manufacturing applications.

The robust 50 taper spindle allows for the use of a wider variety of tooling commonly encountered when machining larger parts, while its advanced design features and highly rigid construction provide stable machining conditions in any manufacturing environment. When your production demands require both size and precision, the DNM 750/50L II delivers exceptional performance that drives manufacturing excellence.

Precision Engineering for Heavy-Duty Machining Applications

The DNM 750/50L II sets a new standard for precision machining of large components through several key engineering advantages:

- Massive Meehanite Cast Iron Structure: The one-piece bed features heavy ribbing to prevent vibration and deformation during heavy cutting operations, maintaining precision even under the most demanding conditions

- Wide-Span Roller Linear Guides: Extra-wide spacing (740mm x2) of high-rigidity roller guides provides exceptional support for the saddle regardless of load distribution, ensuring the table is fully supported with no overhang

- Direct-Coupled Spindle System: The true cartridge-type spindle unit eliminates gears and belts, minimizing noise, vibration, and thermal growth while delivering powerful cutting performance

- Thermal Stability System: Ball nut cooling and oil jacket spindle chiller maintain dimensional accuracy during extended machining cycles, critical for large workpiece precision

- High-Capacity Tool Management: 30-tool automatic tool changer with 2.5-second tool-to-tool change time allows for efficient processing of complex parts requiring multiple operations

- Advanced Control Features: Tool load monitoring and adaptive feedrate control optimize cutting performance while protecting your valuable tooling and workpieces

- Integrated Chip Management: Dual screw conveyors efficiently remove chips from the work area, maintaining a clean cutting environment even during heavy material removal operations

Industry Applications and Manufacturing Solutions

The DNM 750/50L II's combination of large work envelope, rigid construction, and precision performance makes it ideal for demanding applications across multiple industries:

Aerospace Component Manufacturing The aerospace industry requires both size and precision when manufacturing structural components, landing gear parts, and engine housings. The DNM 750/50L II's large table capacity accommodates complex fixtures and sizable workpieces, while its thermal compensation systems maintain critical tolerances throughout extended machining cycles. The high-torque 50-taper spindle excels when cutting challenging aerospace alloys including titanium and Inconel.

Automotive Production Applications Automotive manufacturers value the DNM 750/50L II for machining large transmission cases, engine blocks, and tooling components. The machine's rigid construction provides the stability needed for heavy roughing operations, while its thermal compensation systems ensure dimensional consistency for precision finishing. The high-capacity coolant system efficiently evacuates chips during the high material removal rates required for automotive production.

Energy Sector Components Oil and gas, power generation, and renewable energy components often require machining of large, heavy workpieces with challenging materials. The DNM 750/50L II's 1,800kg (3,968 lbs) table capacity handles substantial components, while its powerful 50-taper spindle provides the torque needed for efficient material removal. The rigidity of the machine structure ensures precision even when cutting difficult materials like stainless steel and high-nickel alloys.

Mold and Die Production The DNM 750/50L II excels at producing large molds and dies with its combination of size capacity and precision. The thermal stability systems maintain accuracy during the long machining cycles typical of mold work, while the high-torque spindle efficiently handles the interrupted cuts encountered in die production. Through-spindle air capability provides effective chip evacuation when dry machining is required for certain mold applications.

FAQ Section

What makes the DNM 750/50 II different from other vertical machining centers?

The DNM 750/50 II stands apart due to its 50-taper spindle, which allows for heavier, more rigid tooling and higher torque output—making it ideal for large or tough-to-cut parts. Unlike many 40-taper machines, the 750/50 II can handle deeper cuts and heavier tools without compromising stability or accuracy. It also includes features like through-spindle coolant, ball-nut cooling, and roller guideways, ensuring top-tier performance in high-demand applications.

What spindle options are available and how do I choose the right one?

You can choose between two spindle options:

8,000 rpm / 29.5 hp / 260.6 ft-lbs torque: Ideal for heavy cuts in hard metals, mold bases, and energy components.

10,000 rpm / 35 hp / 122 ft-lbs torque: Better suited for high-speed aluminum or general-purpose applications where faster spindle speeds are more critical.

Both use the Big Plus CAT 50 interface and offer excellent rigidity and thermal stability. Your choice depends on whether torque or speed is more important to your application.

How does the machine handle thermal stability during long cycle times?

Thermal expansion is managed through a combination of features: ball-nut cooling on all axes, an oil-jacket spindle chiller, and rigid Meehanite castings. These systems minimize dimensional drift and maintain positioning accuracy even during extended machining operations. The machine’s integrated cooling system also enhances the longevity of internal components and reduces setup time fluctuations.

Is the DNM 750/50 II compatible with probing and automation systems?

Yes, it’s fully compatible. The DNM 750/50 II is preconfigured for Renishaw probing systems with an OMI-2T optical receiver and GUI software for spindle and tool setters. This enables automated part setting, in-process measurement, and tool breakage detection. Additionally, with its adaptive feedrate and load monitoring features, the machine is well-suited for unattended or semi-automated environments.

What types of applications is the DNM 750/50 II best suited for?

This machine excels in applications requiring high torque, large tool support, and rigid construction—such as:

Heavy-duty mold base machining

Structural aerospace parts

Energy sector equipment and valves

High-volume production of cast or forged parts

With its 50-taper spindle, high table load capacity, and advanced controls, the DNM 750/50 II is built to thrive in environments where power and precision are essential.

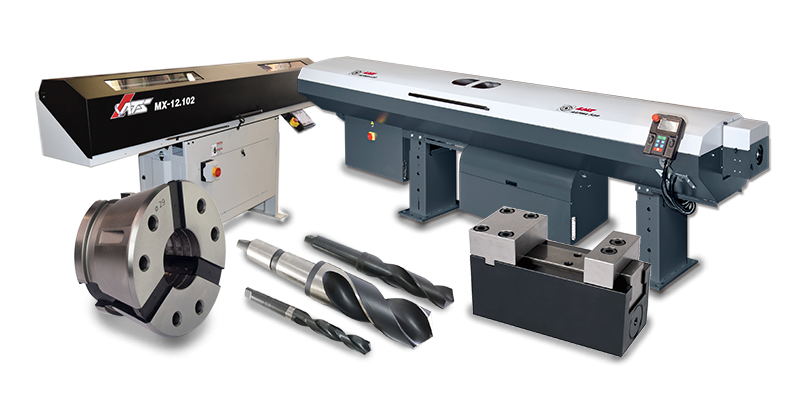

ACCESSORIES

Whether it’s a replacement part or an accessory to boost your productivity, we offer a wide selection of products from a large variety of vendors to bring you the best accessories at the best price.

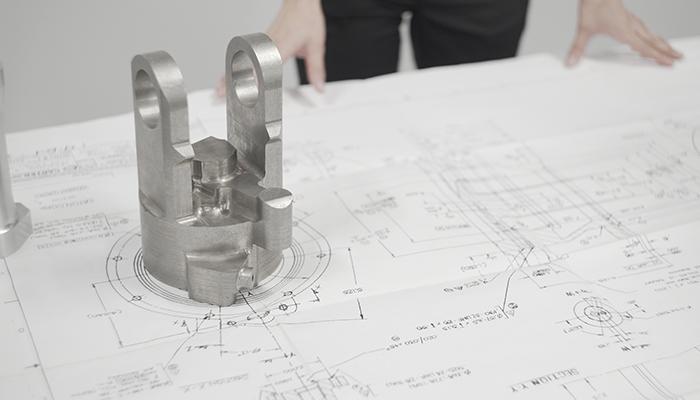

TURNKEY ENGINEERING SOLUTIONS

If you need to:

- Make a part faster

- Adapt your staff or parts to a new machine

- Program a new part

- Utilize the full potential of your machine

Our team of machining experts offer a wide range of Turnkey Solutions to help you make more out of your parts and your machine.