Invigorate your manufacturing process with Ellison Technologies' industry-leading CNC machines. As authorized distributors for DN Solutions (formerly Doosan Machine Tools), we offer a comprehensive range of cutting-edge CNC equipment designed to meet your specific production needs. Our CNC machines deliver exceptional precision and quality control, minimizing rework and ensuring consistent, reliable results.

By automating tasks and optimizing production processes, our machines help you achieve faster turnaround times while reducing operational costs – boosting both efficiency and profitability.

Partner with Ellison Technologies for more than just world-class CNC machinery. Our dedicated support, tailored training programs, and ongoing services ensure you get the most from your investment. Contact us today to discover how CNC machine technology can transform your manufacturing operations.

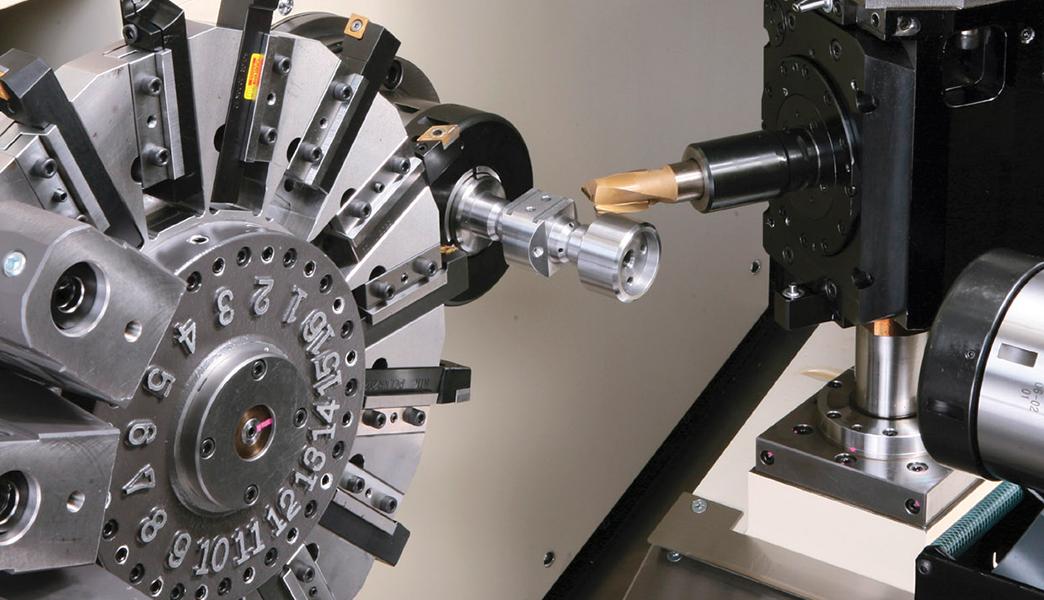

A machining center is a versatile milling or drilling machine that comes equipped with an automatic tool changer built directly into the unit. The workpiece is securely clamped onto the table, providing stability and accuracy during the machining process. Machining centers come in two primary types: horizontal and vertical, each with unique features to accommodate different machining needs. With a machining center, you can enjoy high precision and efficiency, allowing you to streamline your manufacturing processes and achieve outstanding results. Upgrade your machining capabilities today with a top-of-the-line machining center!

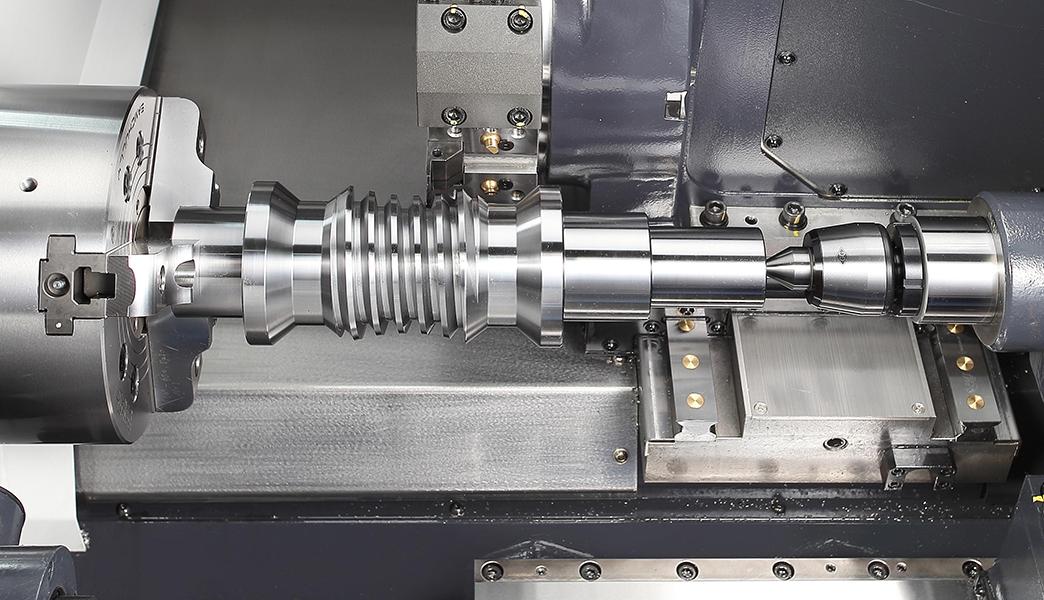

A Turning center, also known as a CNC lathe, is a type of machine that holds a cylindrical, tube-like, workpiece at one or both ends and rotates it while cutting tools shave off layers of material. Lathes produce cylindrically shaped parts, which typically have straight sides and circular ends. Lathes can produce a wide variety of parts, including complex parts with close tolerances or specifications. There are two types of Turning Centers: Vertical Turning Lathes and Horizontal Turning Lathes. While the Horizontal Lathe is more commonly used, sometimes it is necessary to use a Vertical Lathe for larger, heavier workpieces or floor space constraints. The only difference between the two lathes is the angle at which the material is cut.

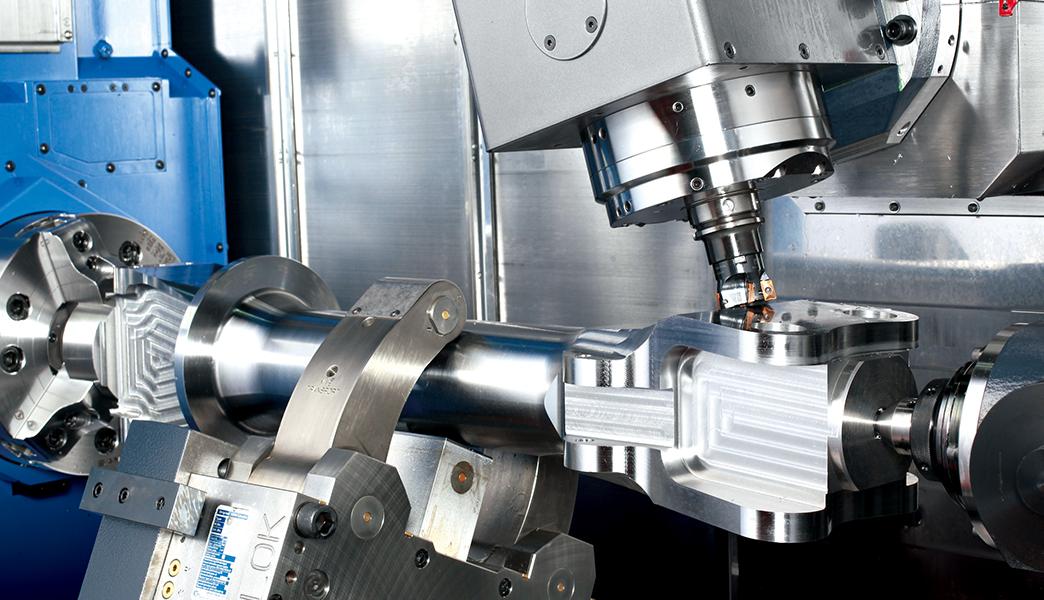

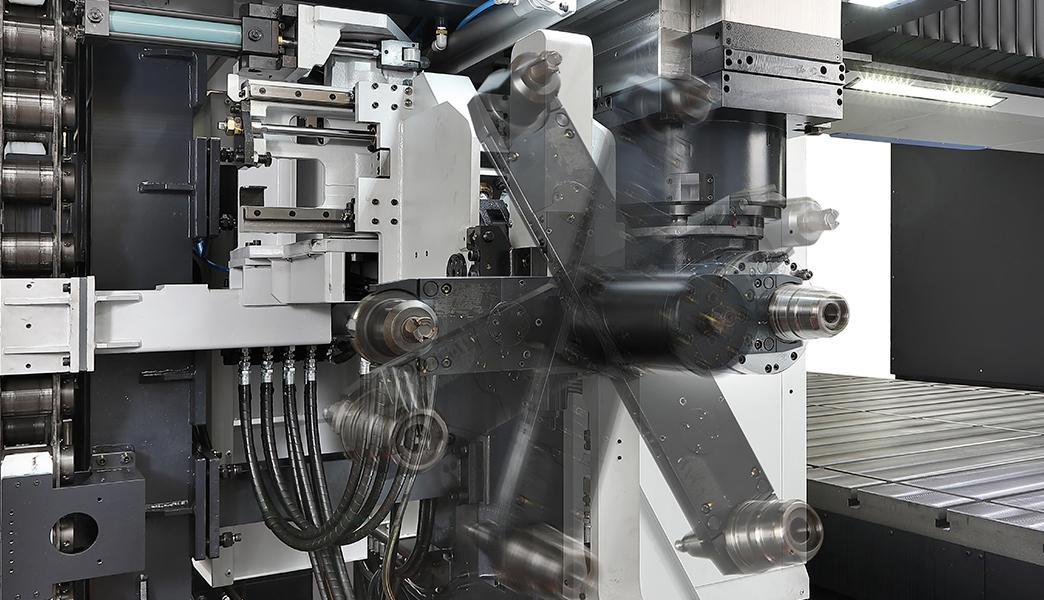

Turn Mill Centers offer the benefits of both milling and turning in one machining center for optimal results. This type of CNC machine tool has many benefits because it merges multiple operations. For example, it reduces setup time, cuts down on operation time, and increases the quality of the part.

5-axis machines are able to move in different directions on five axes simultaneously, or with a 4+1 or 3+2 set up. 5 axis machining centers has a cutting tool that moves across the X, Y and Z linear axes as well as rotates on the A and B axes enableing it to cut the workpiece from any direction. While this capability increases efficiency, it also leads to reduced set-up times of complex parts, fewer errors, and quicker production times.

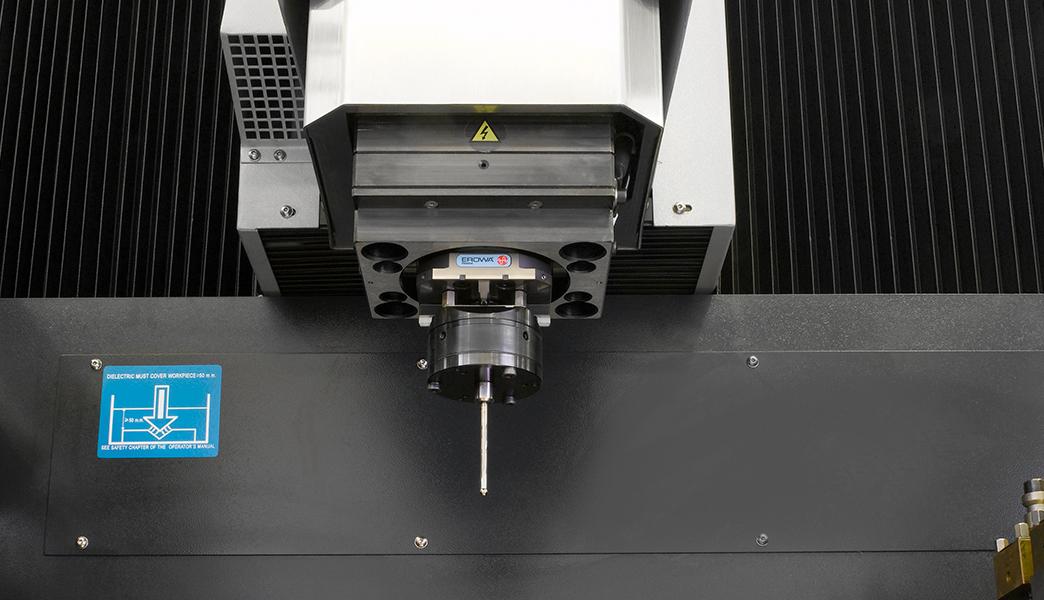

For jobs that require machining complex shapes, extremely hard materials, small workpieces and require very close tolerances and good surface finishes; Electric Discharge Machines (EDM) are the ideal solution to meet your needs. Perfect for the mold and tool making industries, we offer EDM’s with options for die sinking, wire cut, and hole drilling.

Swiss Style Turning machines are perfect for fast, high-production components that vary in size, from small complex parts to long parts that are normally too difficult to machine in a standard turning center. Swiss Style Turning machines are extremely accurate because the material is fed through the guide bushing where it is more rigid, providing a stable platform for fast cycle times and producing intricate workpieces. These machines are commonly used in the aerospace and medical industries to produce high-precision parts with tight tolerances.

These operate in a similar fashion as vertical machining center machines do. The only difference is that they are bigger and produce extremely large parts such as automobile frames and airplane wings.

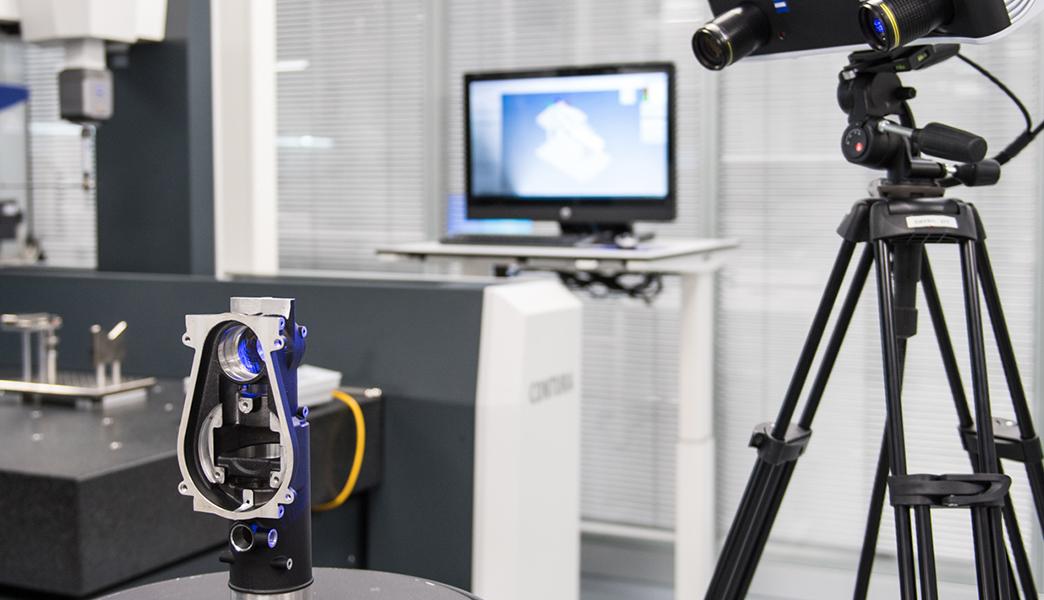

Metrology machines use advanced 3-D software to inspect the accuracy of machined parts in order to achieve strict tolerances. By ensuring that the tolerances have been met, the number of rejected parts is reduced, which contributes to a decrease of unnecessary operating expenditures.

Find Your Perfect CNC Machine at Ellison Technologies

Ellison Technologies is your one-stop shop for top-of-the-line CNC machines. We offer a vast selection to empower your operations, from:

- 3 & 5-axis Machining Centers: Achieve unmatched precision and tackle intricate parts.

- Vertical & Horizontal Mills: Experience versatility and adaptability for core applications.

- Bridge & Gantry Mills: Optimize large-scale production with exceptional efficiency.

Beyond Standard CNC Machines:

Our portfolio extends beyond traditional options:

Turning Centers (Lathes): Address simple turning needs with high accuracy.

Mill-Turn & Multi-Function Centers: Consolidate milling, drilling, and turning for faster production.

Electrical Discharge Machines (EDM): Machine complex shapes and hard materials with superior precision.

Swiss-Style Turning Machines: Produce high-precision components with tight tolerances.

Ensuring Your Success:

Metrology Machines: Guarantee part quality and minimize waste with advanced 3D inspection.

Expert Support: Our team is dedicated to helping you select the right CNC machine and maximize its potential.