Updated: February 4, 2026

Great business ideas can come from surprising places.

Great business ideas can come from surprising places.

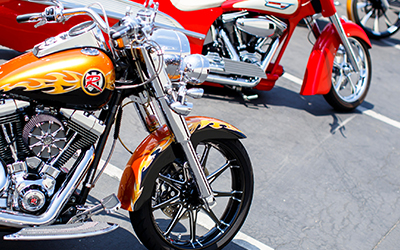

As proof, allow us to present Chuck Frederick, President of Renegade Wheels (Orange, CA). His successful venture began when he bought a Harley Davidson Fatboy in 2003. He designed a pair of custom wheels for his new ride and had them manufactured in a friend’s shop. They were so cool that people began stopping him on the street to ask where they came from. He got the hint. Before long, Renegade Wheels was in business.

At first, all machining operations were outsourced to local job shops. Chuck realized something had to change. “For the first nine years we were in business, we essentially managed machine shops. I saw them growing and buying equipment and realized there was money to be made in machining our own product.”

After learning how to machine hubs and brake rotors on smaller mills, Renegade added a DN Solutions (Doosan) DNM 750 II vertical machining center to the shop in 2016.

After learning how to machine hubs and brake rotors on smaller mills, Renegade added a DN Solutions (Doosan) DNM 750 II vertical machining center to the shop in 2016.  Chuck refers to his custom-made wheels as “jewelry for men,” and he knows the presentation is just as impactful as the product. That’s why Renegade takes extra care with shipping and packaging so that the customer gets a Christmas-like joy out of opening the box. The effort that’s put into packaging shows just how important it is for Renegade to have a machine tool partner that gives them the reliability and performance they need.

Chuck refers to his custom-made wheels as “jewelry for men,” and he knows the presentation is just as impactful as the product. That’s why Renegade takes extra care with shipping and packaging so that the customer gets a Christmas-like joy out of opening the box. The effort that’s put into packaging shows just how important it is for Renegade to have a machine tool partner that gives them the reliability and performance they need.