German engineering accelerates 5-Axis machining

If you’ve been doing something since the late 19th century, you’re probably doing a few things right. That’s certainly the case with HELLER, whose 2,600 employees all over the world work hard to push the machine tool industry forward.

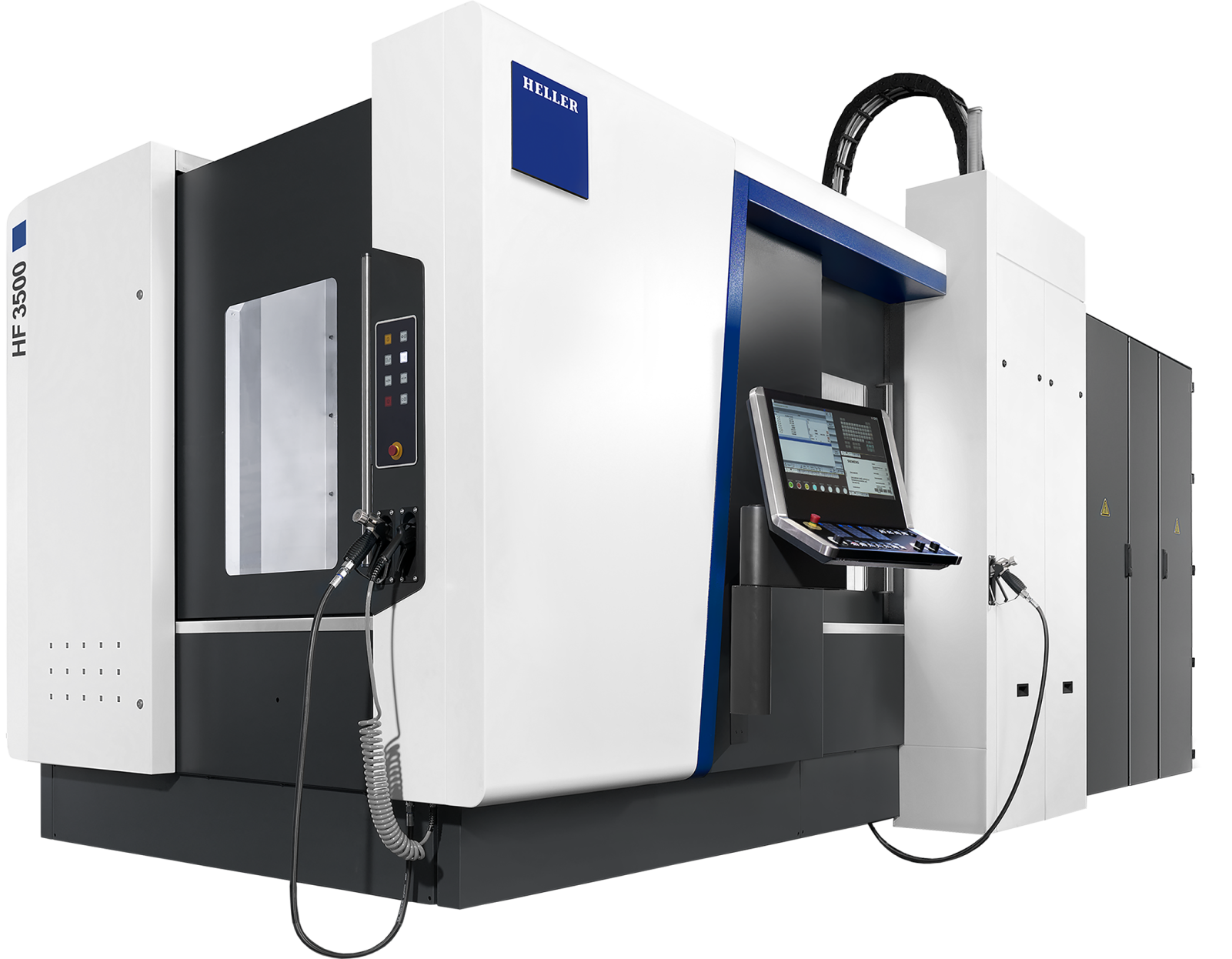

The company has made a name for itself thanks to a legacy of innovation and passion for performance, and those qualities are front and center in their HF Series of 5-axis machines. With a horizontal spindle that moves on the X/Y axes and a trunnion table that moves on the Z, with direct drive technology incorporated in to the A and B axes. the HF probably doesn’t look like most 5-axis machining centers you’re familiar with.

That’s only the beginning.

So why go horizontal?

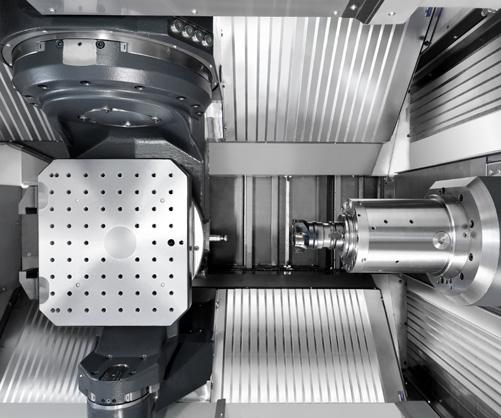

When you see the HF Series move, you’ll get it right away. The horizontal spindle orientation and moving trunnion table allows for a remarkable spindle reach and massive tool projection lengths in a relatively compact footprint.

How remarkable and massive? The HF 3500 has 710 mm (27.95”) of Z-axis travel and can accommodate 450 mm (17.72”) tools. Its big brother, the HF 5500, has a whopping 930 mm (36.61”) of Z-axis travel and handles tools up to 550 mm (21.65”).

There are seven spindle options for the HF Series, and all of them feature narrow spindle necks to maximize reach into the workpiece. The custom designed and built drive systems allow the spindle to maneuver throughout the work envelope quickly and effortlessly.

One additional benefit to the horizontal spindle orientation: optimized chip evacuation. Not only do you have gravity working in your favor, but the trunnion table can be fully inverted, dumping any accumulated chips into the machine bed.

No compromises on rigidity and speed

HELLER builds machines to work in production machining environments, so they never skimp on build quality and machine rigidity. The HF Series is no exception.

The HF features a beefy machine design and construction that simply cannot be beat. The rigid cast iron machine bed serves as a base for the robust steel traveling column that houses the spindle. The gantry drive is made from cast iron for optimized damping, and includes a counter bearing as standard for increased support. A second ballscrew in the gantry drive for even better rigidity is optional.

Even though the HF Series features ball screw drives, these machines have rapid traverse rates of up to 90 m/min (3,543 IPM). This gives you the reliability and rigidity of ballscrews with speeds that compete with the fastest linear drive machines in this class.

There are seven HSK spindle options made by HELLER to tailor your HF machine to your unique applications. Need power and torque? Three HSK100A spindles are available to tackle your tough machining applications. Got the need for speed? Choose from four HSK63A spindles ranging from 12,000 all the way up to 30,000 RPM.

Precision and performance 24/7

As mentioned, HELLER machines are built for precision jobs in production machining environments. While 5-axis machining is inherently more precise thanks to the reduced setups, the HF Series brings added features to benefit precision and uptime even further.

All machining axes in the HF feature direct, absolute and integrated measuring systems for high precision positioning. Heat management solutions include chilled spindles, drives and control cabinets as well advanced active thermal compensation systems.

For companies that can’t spare a moment’s downtime, you’ll be thrilled to meet HELLER’s Zero Spindle system. In the event of a spindle crash, the front end of the spindle can be unbolted and switched out in less than an hour. While no one looks forward to a crash, it’s good to know that with HELLER you won’t be down for days or weeks.

Your next step: talk to Ellison

There is perhaps no dealer partner in all of North America better equipped to help you make more parts, more money and more for the legacy you’re building.

If you have parts and applications that require the kind of high-end performance and reliability HELLER can bring, reach out to us for a discussion about the HF model that’s right for you.