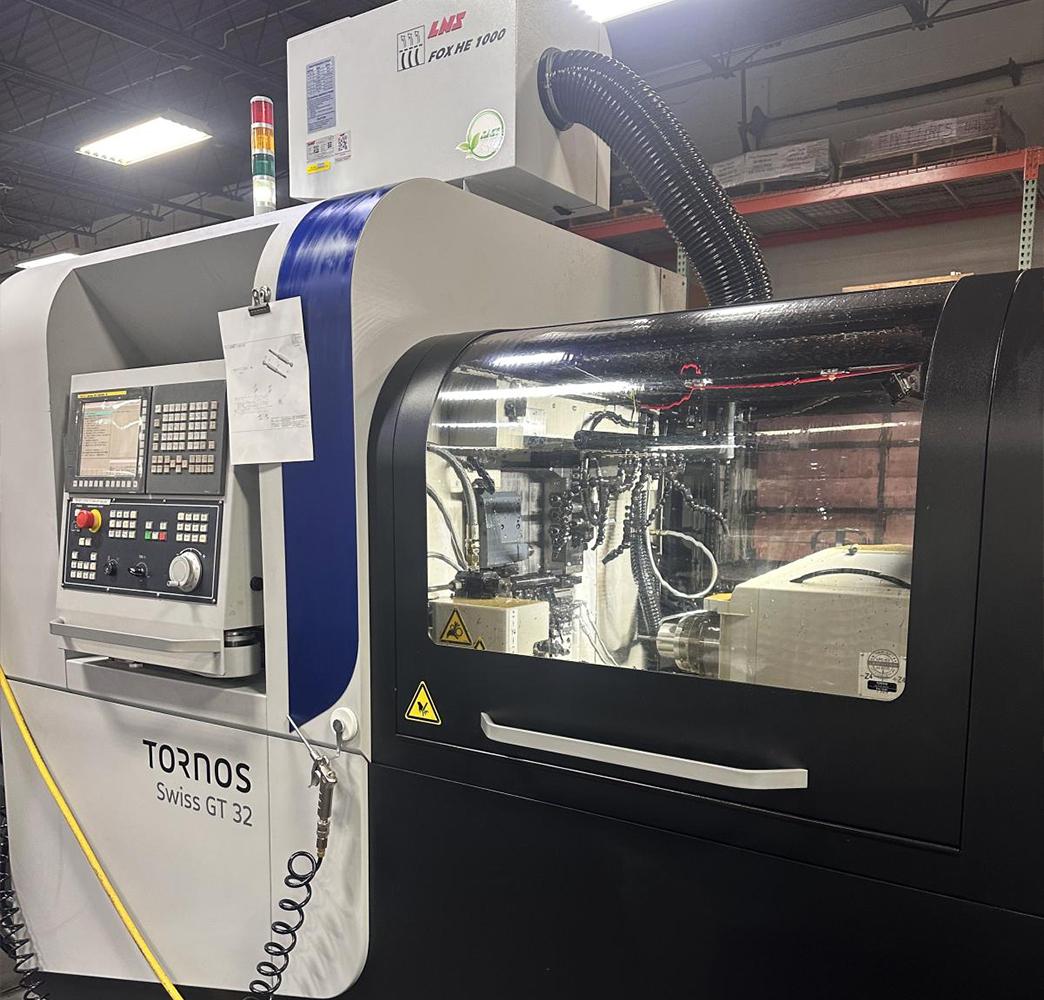

Forward Technologies Expands Beyond Chucking

with the Tornos Swiss GT 32 B

Forward Technologies, Inc. (FTI) has earned its reputation as a precision CNC machine shop by delivering complex parts in a wide range of materials — from plastics and metals to aerospace-grade alloys. Offering full-service manufacturing solutions, Forward handles everything from production to assembly, including specialized processes like heat treating, plating, and third-party inspections. This turnkey approach allows customers to receive finished parts without the complexity of managing multiple vendors.

The Challenge: Evolving Beyond Chucking

As industry demands evolve, Forward recognized the need to diversify beyond its core chucking operations to remain competitive in a changing manufacturing landscape.

“We wanted a new machine that would help us move beyond traditional chucking,” said Brad Meyers, President of Forward Technologies. “We want to be sustainable and diverse to continue having a successful future.”

The Solution: A Trusted Partnership

To make that leap, Forward turned to Ellison Technologies and longtime sales representative Mike Sess from the Cincinnati office. With years of positive experience, Brad and his team trusted Ellison’s technical guidance and commitment to service.

“We’ve had such good success with Ellison and the service they provide,” Meyers said. “That gave us the confidence to choose Tornos, knowing we’d have support every step of the way.”

Working closely with Forward, Mike recommended the Tornos Swiss GT 32 B — a machine that offers the precision, speed, and flexibility needed to support their growth into more complex part production.

Why the Tornos Swiss GT 32 B?

The Tornos Swiss GT 32 B delivers the high-performance machining capabilities Forward Technologies was looking for. With dual identical spindles, up to 40 tools (including 14 rotating), B-axis machining, and user-friendly programming with TISIS software, the machine makes producing intricate components faster and more efficient.

One standout feature for Forward was the counter spindle design.

“One of the big drivers that helped us pick a Tornos over other manufacturers was the counter spindle,” Meyers explained. “The counter spindle on a Tornos is the same as the primary spindle.”

That dual-spindle setup allows for consistent performance on both ends of the part — improving accuracy, reducing cycle time, and enabling greater part complexity.

A Partnership Built on Trust

While the machine’s capabilities are impressive, what truly sealed the decision for Forward was the ongoing support and service they’ve come to expect from Ellison.

“We know Ellison stands behind what they sell,” said Meyers. “If there’s a challenge, they’re there with a solution. That relationship gives us confidence to take on new projects.”

For Ellison Technologies, building long-term partnerships like this is exactly what they strive for.

Looking Ahead

With the Tornos Swiss GT 32 B now fully integrated into their operations, Forward Technologies is positioned for long-term growth and diversification — supported every step of the way by Ellison Technologies.

Take Your Next Step in Precision Manufacturing

Contact us today to explore how Ellison Technologies and the Tornos Swiss GT 32 B can help you expand beyond traditional chucking into more complex, diversified production.