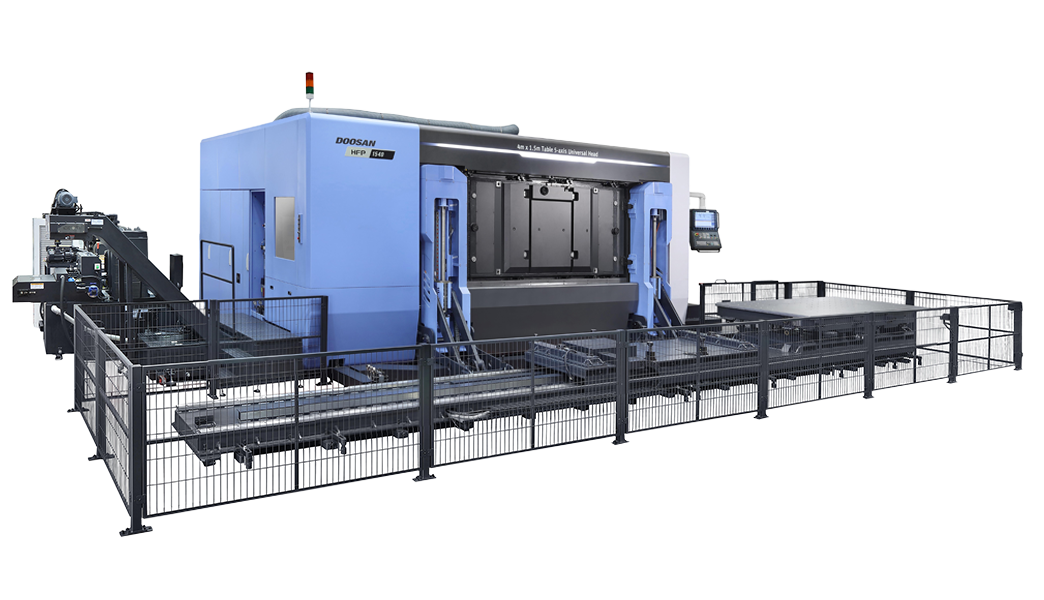

Large Platform Machines in the Market

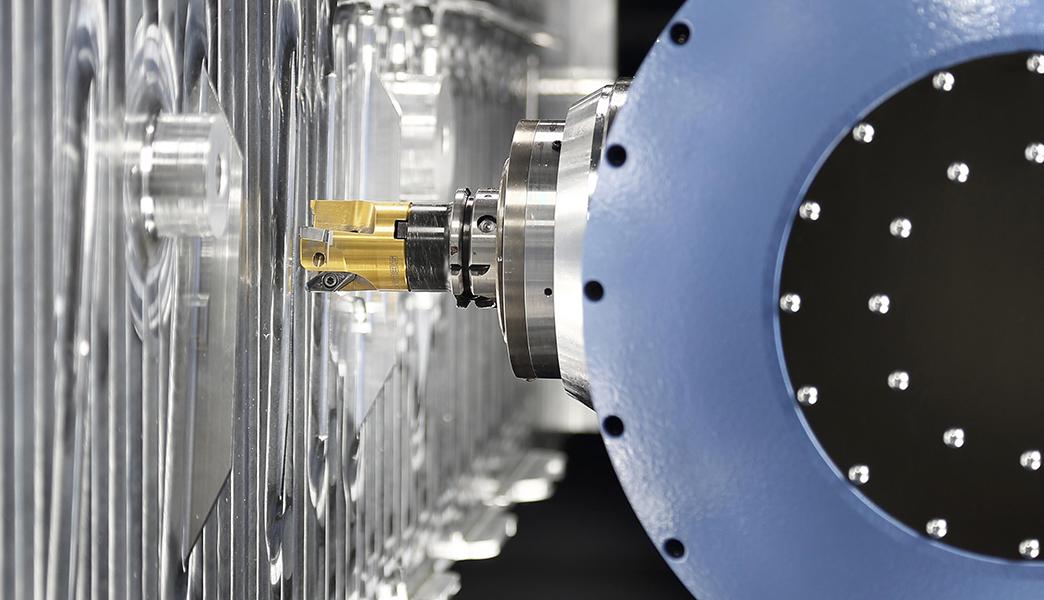

On average in the U.S. there are 9,175 small machining centers and 480 large machining centers sold per year. Although large machining centers only make up 5% of the total, the number of large machines sold each year has grown 190% over the last 4 years. Remarkably, this growth has been consistent during two manufacturing recessions. The initial assumption is that big manufacturers in the aviation, transportation, and agriculture industries are the primary buyers of large platform machines, but in fact, it is machine shops that own 45.6% of all the machines in the market. Statistically, a machine shop in your area will buy a large machine, likely with 5-axis capabilities. Will you wait for the competition to get ahead or will you become the competition?