You are here

News

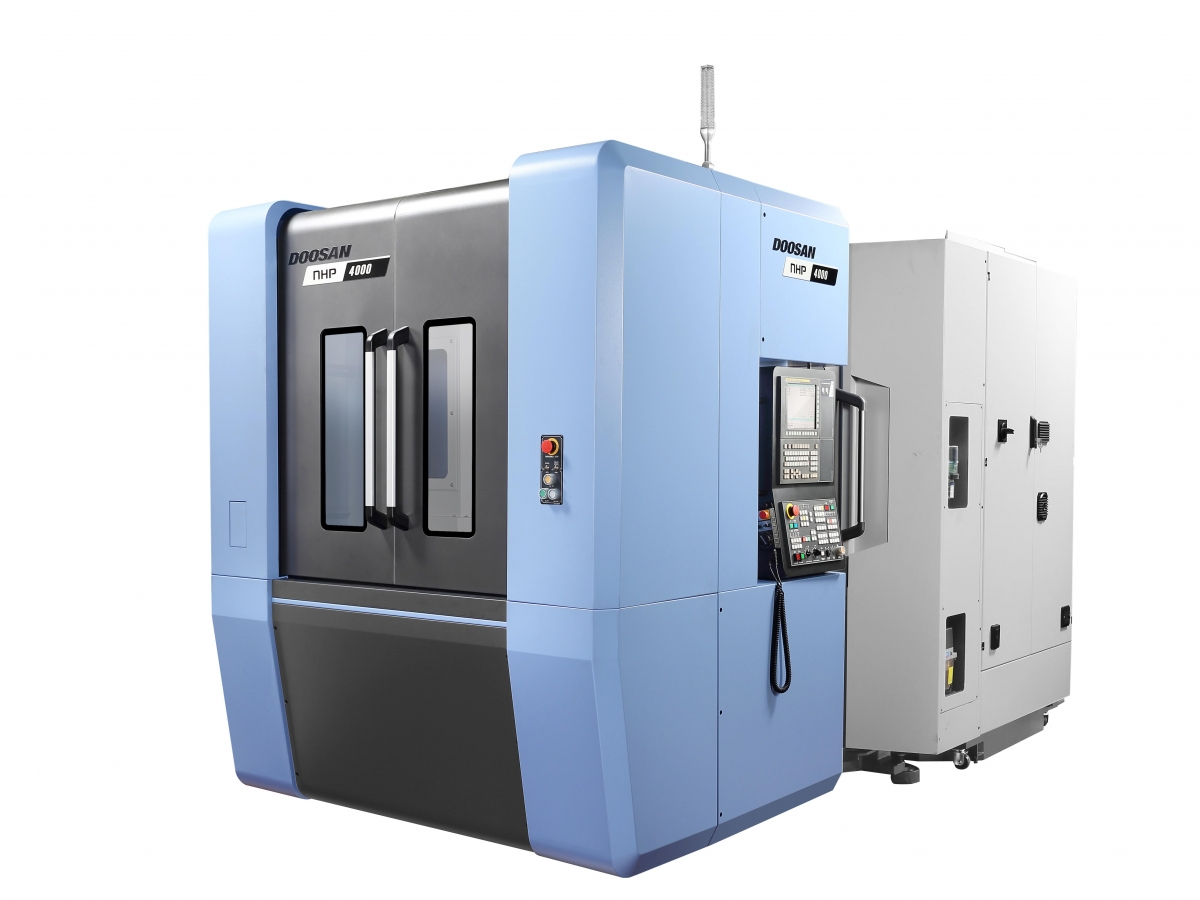

Doosan Introduces New NHP High Productivity Horizontal Machining Centers

Doosan Machine Tools is pleased to introduce the new NHP Horizontal Machining Center series, built from the ground up for rapid metal removal rates. Designed to meet the manufacturing demands of industries including automotive and aerospace, the 400mm pallet NHP 4000 and 500mm pallet NHP 5000 are feature-rich yet configurable for a range of applications.

The NHP machines come standard with a 15,000rpm spindle with 40 horsepower and 169 ft-lbs of torque. For heavy cutting, a high-torque 15,000rpm spindle with 223 ft-lbs is available, and a 20,000rpm spindle is in development for customers with higher speed precision applications.

Machine highlights:

Machine highlights:

- 1G Acc/Dec for all axes

- 15,000 & 20,000 RPM spindle options

- 40 and 50 HP Spindle Motors

- Class leading torque, up to 225 ft/lbs.

- Ballscrew shaft and bearing cooling

- 230 PSI through spindle coolant

- Through spindle air

- Center through chip evacuation

- 10 Flood coolant nozzles

- Spindle thermal displacement compensation

- 3 point leveling

- MT Connect ready

- BIG PLUS Spindle

- Easy to automate – from 5 to 72 pallets

- Adaptive federate control

- Tool load monitoring

- Renishaw probe ready

- FANUC 31i-B Control

- FANUC’s Manual Guide

- 2 year parts warranty

“The new NHP Series machines deliver the productivity and precision that manufacturers need to stay competitive,” states Jim Shiner, Director of Sales and Marketing at Doosan Machine Tools America. “From the spindle to the ATC to the APC, we’ve fine-tuned every component on these horizontal machining centers for non-stop world-class performance.”

Up to 1G acceleration/deceleration on X, Y and Z-axes significantly enhances productivity, delivering productivity increases as high as 25% over the previous model. Ball screw shaft and bearing cooling systems keep the temperature of fast moving axes stable, ensuring precision machining.

The new random access disc-type tool magazine allows high-speed 0.9 second tool-to-tool and 2.3 second chip-to-chip times. In addition to minimizing non-cutting time, this design also reduces vibration, resulting in more stable operation.

In optimizing the construction of the machine, the footprint of the NHP has been reduced by 15% compared to the previous model, yet the machining area has been expanded by 24%. The three point leveling design makes machine installation and maintenance much more convenient. The center-through bed chip management evacuates large volumes of chips quickly for enhanced efficiency.

The pallets can accommodate loads of up to 400kg (880 lbs), for the NHP 4000 and up to 500kg (1100 lbs) for the NHP 5000, and both through-pallet and overhead hydraulic fixturing options are available. Additionally, the APC has been refined to achieve a 27% faster indexing time.