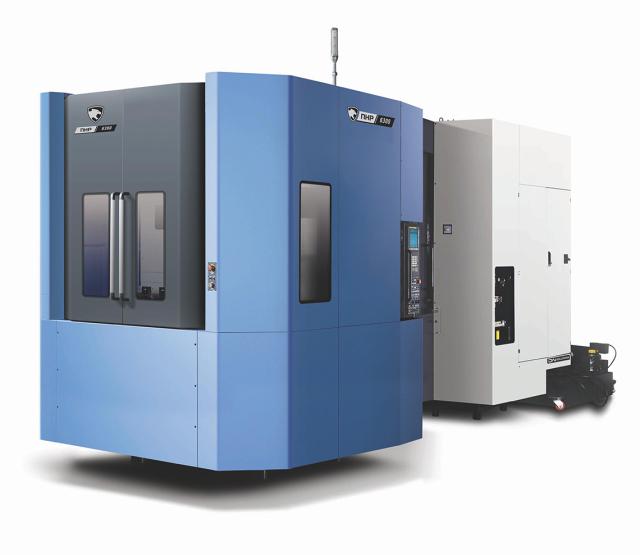

Unleash High-Volume Production with Ellison Technologies' HMCs

Ellison Technologies offers a comprehensive selection of horizontal machining centers (HMCs) engineered to meet the demands of modern manufacturing. Our HMCs provide the perfect balance of speed, accuracy, and reliability, making them ideal for high-volume production environments.

Engineered for Peak Performance:

These top-of-the-line HMCs deliver the perfect balance of speed and accuracy, ideal for tackling demanding production runs in your machining operations.

- DN Solutions HMCs: Famed for their minimal idle times and rapid tool changes, these machines maximize production throughput while maintaining exceptional part quality.

- HELLER HMCs: Experience unwavering precision with HELLER's advanced machining technology. HELLER HMCs excel in applications requiring tight tolerances and intricate details.

- NTC HMCs: Built for versatility and reliability, NTC HMCs handle a wide range of materials with consistent results.

Elevate Your Machining Capabilities:

- Increased Production Volume: Meet tight deadlines and boost overall output with the exceptional speed and efficiency of these HMCs.

- Reduced Operating Costs: Minimize downtime and manual labor through features like automatic tool changers and optimized chip management.

- Enhanced Part Quality: Deliver consistently precise parts with every run, reducing rework and scrap rates.

- Improved Shop Floor Efficiency: Streamline workflows and optimize machine utilization with user-friendly controls and rapid setup times.

Ellison Technologies: Your Trusted HMC Partner

Our team is here to help you select the perfect HMC from DN Solutions, HELLER, or NTC to meet your specific needs and applications. We'll ensure seamless integration into your existing workflow and provide ongoing support to maximize your investment.

DN Solutions has a proven record of successful machine installations in the U.S. market for over 30 years. It offers a diversified product line, with choices ranging from small lathes and mills to heavy duty machining centers to very large double column and boring mills.

NTC: Founded in Japan in 1950, NTC today has facilities across Asia, North and South America, and Europe. NTC’s full line-up is engineered and built in Japan for long-lasting, trouble-free operation. NTC is a global leader in Grinding Machines, Crankshaft Millers, Machining Centers, Transfer Machines and Wire Cutting Saws. It is the premier supplier for machine shops specializing in aftermarket parts and prototypes to large automotive manufacturers. Customer satisfaction, durability, quality and environmentally-friendly manufacturing is NTC’s focus in surpassing expectations and making it better.