Robotic Automation is one of the quickest ways to increase return on investment on a machine tool purchase.

We have been educating our customers for over 30 years on the benefits of automation. Increased productivity and lowered costs are some of the benefits realized. Once we address the most common myths, manufacturers are open to considering a robotic solution.

MYTH #1: ROBOTIC AUTOMATION IS EXPENSIVE & HARD TO JUSTIFY.

MYTH #1: ROBOTIC AUTOMATION IS EXPENSIVE & HARD TO JUSTIFY.

Automation deployment delivers one of the highest returns on investment. It maximizes profitability through efficiency increases, lights-out and unattended operations, setup reduction times, increased quality and reduced overall manufacturing costs. A robotic system has a payback period of about 1 year on average, with some projects as short as 6 months on existing equipment. The overall system payback on a new machine tool purchase is dramatically reduced when adding a robot. This also allows employees to focus on operational improvements instead of basic, unskilled tasks.

MYTH #2: ROBOTS DISPLACE AMERICAN JOBS.

MYTH #2: ROBOTS DISPLACE AMERICAN JOBS.

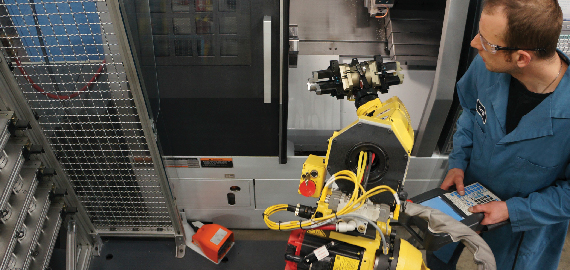

Increased international competition is forcing American manufacturers to make two choices: accept the status quo and settle for ever shrinking profits in the race to the lowest price; or adopt new technologies to become competitive on a global scale and grow their business. Automation is key to lowering part cost. When our American-made products are price competitive, manufacturing flourishes here and companies hire more people in higher skilled occupations. By keeping manufacturing here, higher paid jobs are required to operate, program and maintain these systems.

MYTH #3: NO FLEXIBILITY IN PRODUCTION

MYTH #3: NO FLEXIBILITY IN PRODUCTION

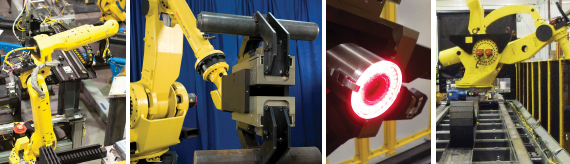

Robots are NOT just for high production runs anymore. When machine efficiency increases by 30% or more with robotics, changeover and small lots become minor concerns. Similar to machine tools, robots change over from job to job by utilizing vision, increased program storage and auto gripper changers. The changeover time is usually the same or quicker than changing over one of the CNC machines. Quick change-over with auto grippers and vision allows for different sizes and shapes of parts to be part of the same run.

Ellison Technologies has the resources to develop the best automation systems tailored to improve productivity and overall profits for all company sizes and industries served. Our approach includes taking a full assessment of the unique conditions in each manufacturing facility and proposing the optimal solution.

When you are ready to explore an automation solution, contact us for a complimentary review of your application.