ChipChat: VMC vs. HMC

In the machining and manufacturing market, machine shop owners need to stay competitive, productive, and profitable. Whether it is through the technology they invest in or improvement made to their process, shops need to adapt to stay competitive. Today we are focusing on the technology that shops use to make their parts and how they are can maximize their productivity through the use of vertical and horizontal machining centers. Read along and watch our recorded ChipChat webinar, VMC vs. HMC, as Ellison Technologies Los Angeles Business Manager, Tony Burns, takes us through the advantages and disadvantages of vertical and horizontal machining centers.

If you missed the webinar, continue reading and view the recording.

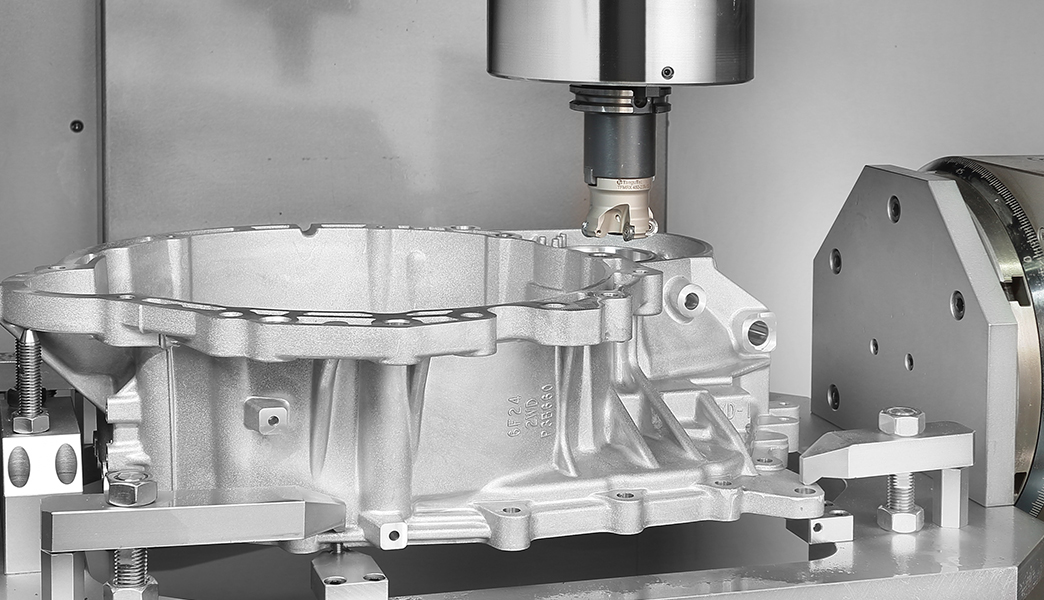

Vertical Machining Centers (VMC)

For decades vertical machining has been the tried and true method for machining parts. For most 3 axis parts, VMC’s fit the bill as an affordable milling solution with features and options to make it more productive and reliable. Features such as high speed spindles, rigid table and structure, pallets, rotary workholding and vices, and robotic loading and unloading for parts. VMC’s were also easier to program, more common amongst machinists, and had a shorter learning curve. With the many benefits and additional options to make VMC’s more productive, they still fell short due to poor chip and coolant flow, small tool capacity, lack of automation options such as bar feeders and pallet changers, and frequent downtime caused by single work envelope loading/unloading, operator breaks and lunches, and first article inspections. When your spindle isn’t machining, you’re not making money.

For decades vertical machining has been the tried and true method for machining parts. For most 3 axis parts, VMC’s fit the bill as an affordable milling solution with features and options to make it more productive and reliable. Features such as high speed spindles, rigid table and structure, pallets, rotary workholding and vices, and robotic loading and unloading for parts. VMC’s were also easier to program, more common amongst machinists, and had a shorter learning curve. With the many benefits and additional options to make VMC’s more productive, they still fell short due to poor chip and coolant flow, small tool capacity, lack of automation options such as bar feeders and pallet changers, and frequent downtime caused by single work envelope loading/unloading, operator breaks and lunches, and first article inspections. When your spindle isn’t machining, you’re not making money.

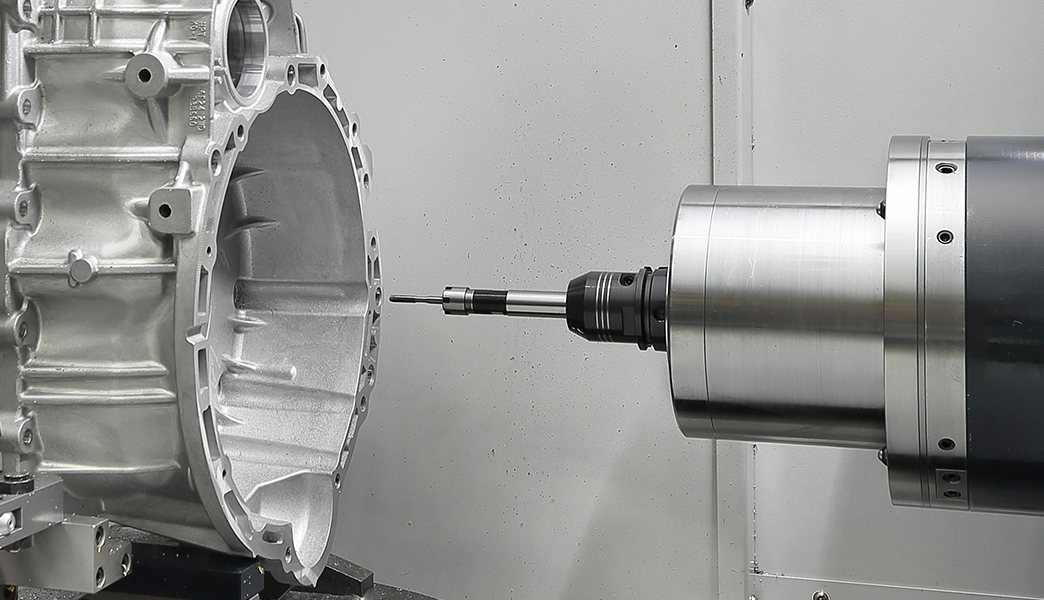

Horizontal Machining Centers (HMC)

Unlike VMC’s, Horizontal Machining Centers present a much larger breadth of benefits and features that make them overall more productive and profitable. Rather than a horizontal table and vertical spindle, HMC’s feature a rotating horizontal pallet along with a horizontal spindle that can achieve 4 axis machining with most having options to reach up to 5 axis. HMC’s generally feature a dual palleted system with automatic pallet changer to allow uninterrupted machining during loading and unloading operations. Additionally, HMC’s are supported with large tool magazines, rotating and linear pallet systems to further expand your machining capacity with unattended operation, and frees up your operators to perform other tasks to help grow your business.

Unlike VMC’s, Horizontal Machining Centers present a much larger breadth of benefits and features that make them overall more productive and profitable. Rather than a horizontal table and vertical spindle, HMC’s feature a rotating horizontal pallet along with a horizontal spindle that can achieve 4 axis machining with most having options to reach up to 5 axis. HMC’s generally feature a dual palleted system with automatic pallet changer to allow uninterrupted machining during loading and unloading operations. Additionally, HMC’s are supported with large tool magazines, rotating and linear pallet systems to further expand your machining capacity with unattended operation, and frees up your operators to perform other tasks to help grow your business.

Changing the Way We Think

Although there are several benefits presented by HMC’s, each shop can have a place for both types on their floor. On average, most VMC’s achieve a 30% spindle utilization which is caused by machine and spindle downtime. In order to achieve world class excellence, shops should achieve 85% spindle utilization. In a 40 hour work week, that is 12 hours versus 34 hours of cutting time, and for a 10 minute part, that is 72 parts produced vs 204. More spindle machining time, more parts, more money.

For shops only using VMC’s, the old way of thinking was to focus on improving cutting time, maximizing heavy cuts, adding more VMC’s, and maxing out the load and production on each machine while increasing overhead costs of lot sizes and labor. The new reality of thinking should be to focus on reducing the time of non-value-add operations, fewer operator touches, improving quality rather than speed, and reducing the need for larger lot sizes by enhancing the productivity and efficiency of each machine.

LJL Engineering Co. – Laszlo Lak joins our webinar and discusses his journey from humble beginnings as a machinist to becoming the owner of LJL Engineering Co., and how he has made the switch from VMC’s to HMC’s. By switching to HMC’s, Laszlo reduced the production time of one of his parts from 2-2.5 weeks down to 4 days. After reevaluating the way he was machining his parts, Laszlo acquired another HMC and began machining more of his parts with the HMC instead of his VMC’s.

Be sure to listen to the recorded webinar to discover the full details of VMC’s versus HMC’s, Laszlo’s switch to HMC’s, and how you can MAKE MORE parts, time, and money.

Want to Know More?

For more information or questions on VMC's and HMC's, contact cncinfo@ellisontechnologies.com.

View our other recorded ChipChat webinars.