Build A Quote

Instant customized machine quotes. Build your quote today!

In-stock Promos

Shop our rotating selection of in-stock machines and cobots from our premier builders.

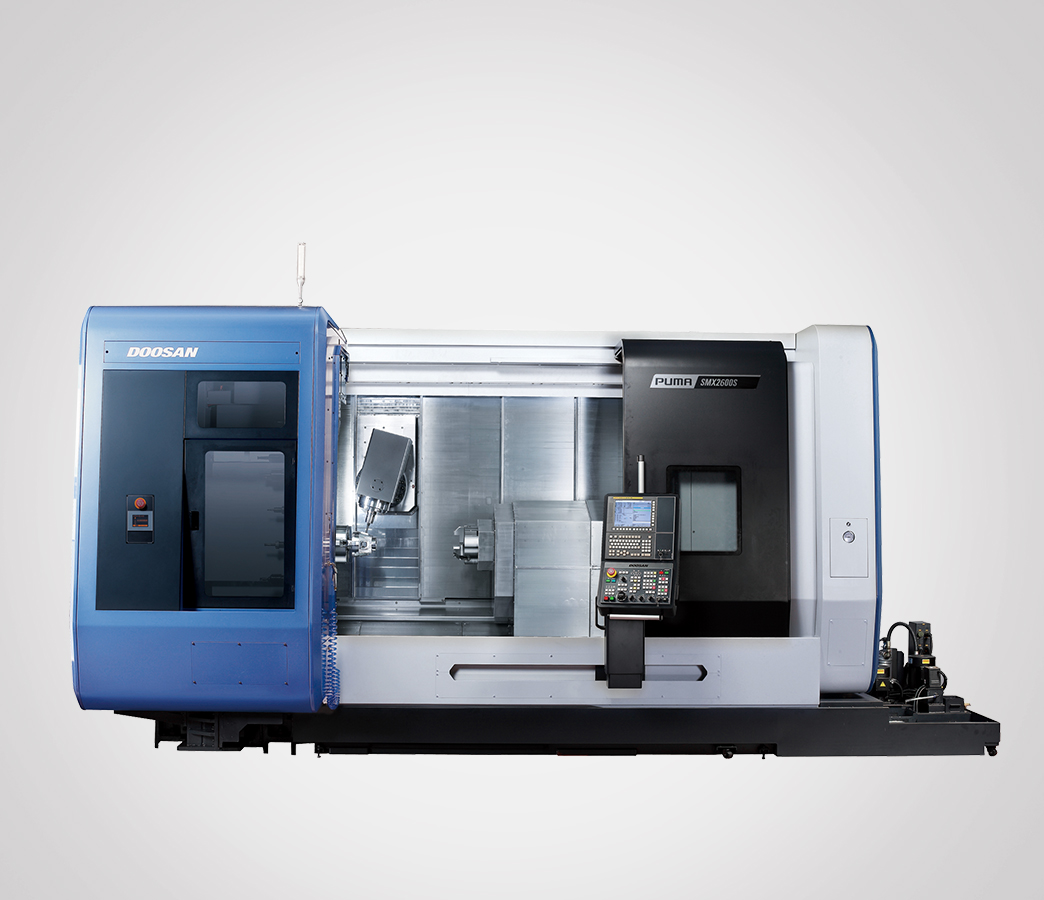

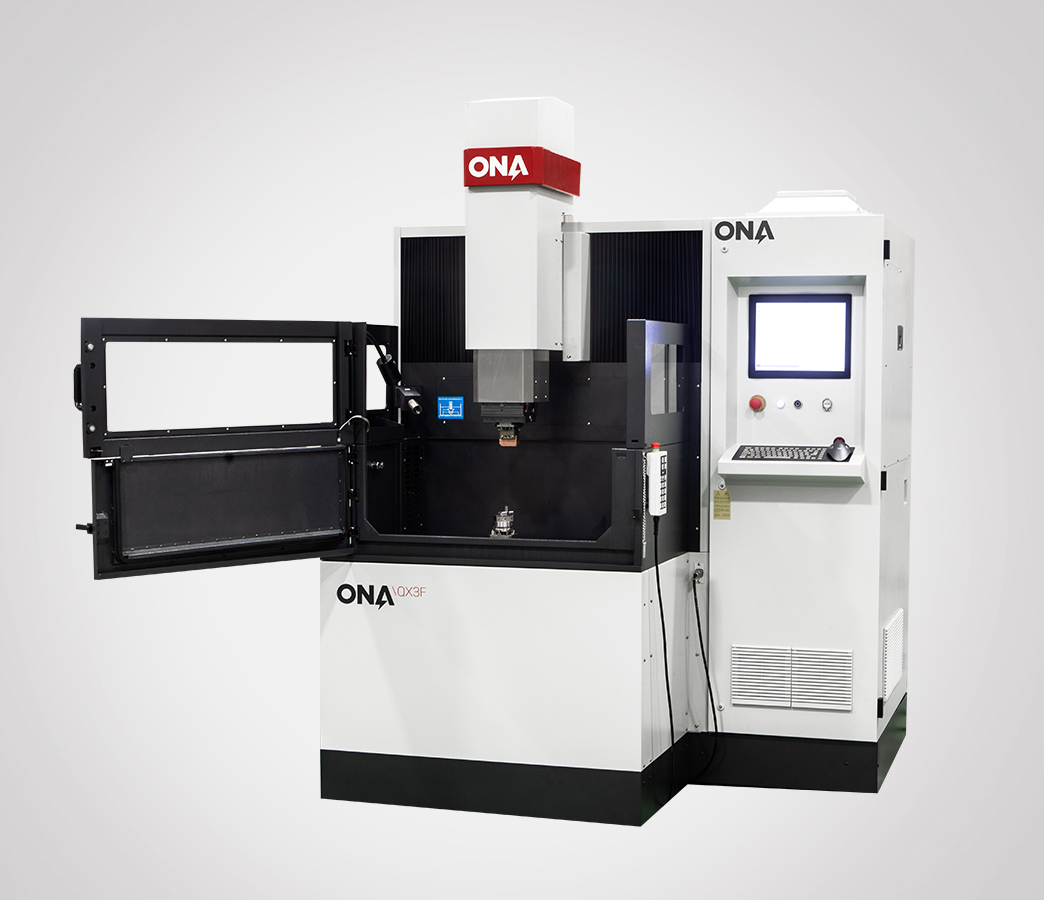

TECHNOLOGY

We’ll collaborate and provide the best solution for your shop. We’ve got just what your application needs with our full product offering in the latest CNC machine tool technology: horizontal turning centers, 3 – 5-axis vertical machining centers, multi-tasking mill turn machines, Swiss-type lathes, grinding machines, EDM, Additive, metrology and the list goes on…

ONE SOURCE SUPPORT

Minimizing your downtime is our business.

Helping you get the most from your equipment investment is our top priority. We have the best engineers in the industry, local to your area, that provide post-install technical support aimed at optimizing your machines as quickly as possible.

Whether you need a replacement part, spindle repair, or to add an accessory to your machine, our dedicated parts and spindle rebuild teams work closely with our builders and major suppliers to provide fast lead and delivery times to keep your machine shop running.